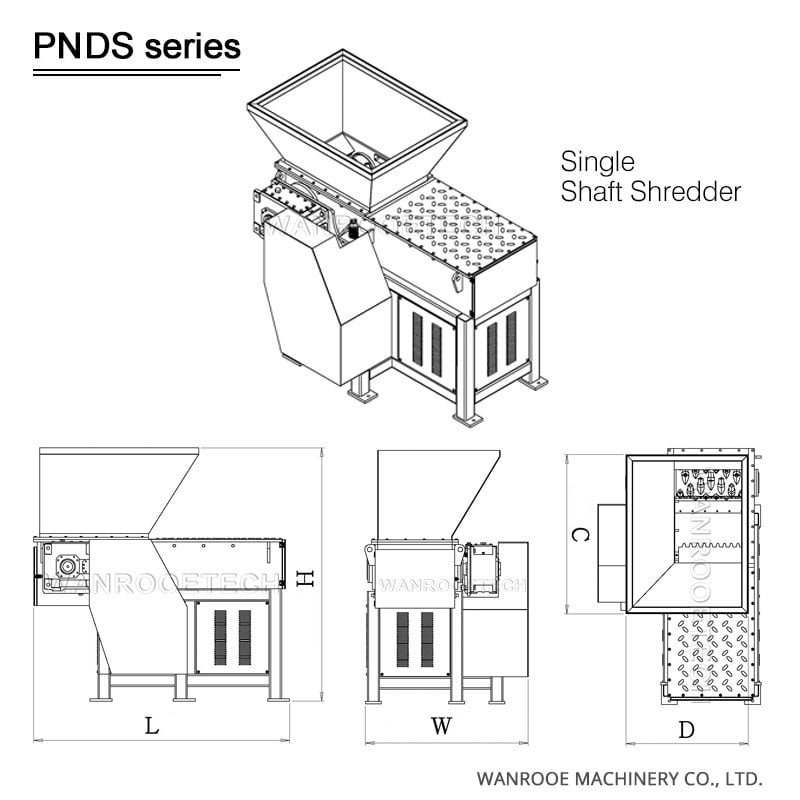

Waste Wood MDF Plywood Board Wood Pallet Shredder Machine Description:

Waste Wood MDF Plywood Board Wood Pallet Shredder Machine is aimed at the characteristics and performance of wood, wood pallets, tree roots. It adopts a special design, combined with PLC control, which makes the machine's hydraulic system and drives the system to a flexible and efficient state. The knife can be used multiple times, increase the blade life, use the variable frequency control hydraulic system to increase the productivity, the heavy wood tear machine uses a double drive, the liquid coupling flexible transmission, so that the machine is smooth, slowing the impact, and improve the impact Machine life. Yield can reach 0.5-1t / h.

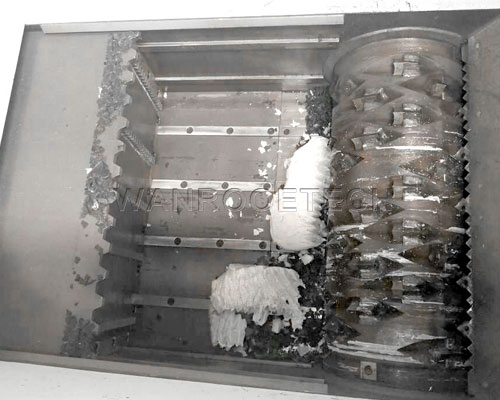

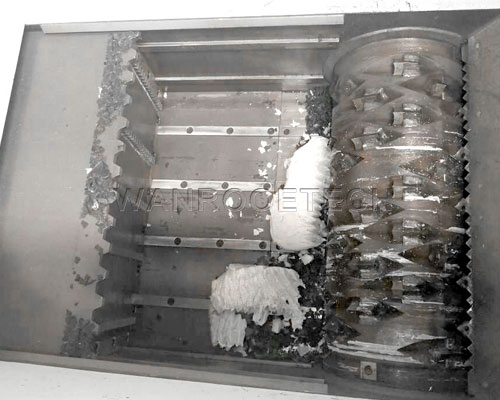

Waste Wood, MDF Plywood Board, Wood Pallet Shredder Machine uses the interaction of movable cutter heads and fixed knives to tear, cut and extrude the material into small size. It can be available for shredding a wide range of materials including plastic, wood, rubber, and paper, etc. The cutter head is consists of a basic shaft and pieces of quadrangle cutter. There are four edges that are easy to change. 'V' shaped rotary cutters are fixed on a single shaft. The fixed cutter is mounted at an angle adjacent to the rotary cutter to achieve better cutting. The material is grabbed between 'V' shaped rotary cutters and fixed cutter shreds repeatedly. During the grinding process, the evenly cutting, saving of energy and reducing of noise are ensured by the installation of 'V' shape rotor knives. Also, the knives are very easy to install and remove.

Single Shaft Shredder 'V' shaped blade:

Waste Wood MDF Plywood Board Wood Pallet Shredder Machine Working principle:

The motor drives the shaft to make the knife rotates at high speed, the material is put between the knife shaft and fixed knife, the materials are shredder, the qualified size will discharge from the screen mesh, the oversize material will be sent back for re shredding. The final product size can be adjusted by changing the final product size.

Waste Wood MDF Plywood Board Wood Pallet Shredder Machine Components:

|  |

Pusher System Reinforced baseplate can reduce the impact caused by material entering the cutting chamber. A dust collection device is equipped at the bottom of the pusher system to guarantee the long-term stable performance of internal components. | Heat treated rotor knives Special DC53 steel (hardened) four edges use before the replacement |

|  |

V-cutting rotor design with staggered cutter positioning | Wear Resistant Tungsten surface coating for abrasive applications |

|  |

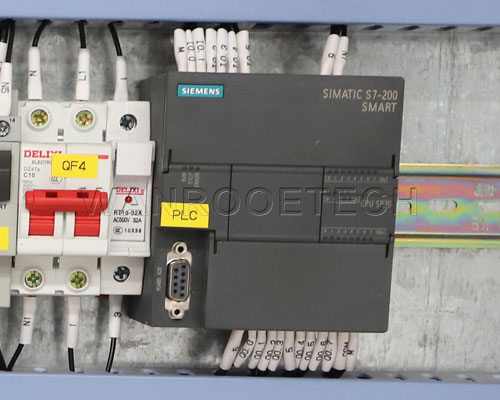

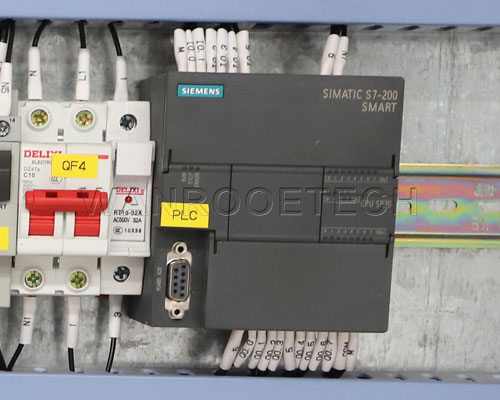

Control panel Equipped with independent and reliable electrical control panel like SIEMENS PLC control system, DELIXI contactor, SCHNEIDER Electric, etc. Manual & automatic operational modes to choose, quite flexible and safe.Motor overload protection.

| Screen Unit Wide range of screens with a variety of configurations and mesh sizes are replaceable based on customers' production requirements. The paper shredder will automatically stop while opening the screen unit to ensure operator safety. The screen is produced and mounted in sections, allow for easy maintenance. |

|  |

PLC control Making it easier for fault diagnosis and maintenance. | Hydraulic Station The pressure and rate of flow can be adjusted according to different materials. |

Waste Wood MDF Plywood Board Wood Pallet Shredder Machine Technical Features:

1.The shredder single shaft for plastic with the big feeding mouth, can put the big plastic or rubber product freely.

2.The rotary and cutting blade with edge of a special design can get very high efficiency and high capacity.

3.The shredder single shaft for plastic is controlled by PLC system; the blade can rotate in opposite direction and close automatically if something unexpected happens; with very high safety service.

4.The shredder single shaft for plastic runs slowly with low noise and is less dusty.

5.The blade material with special alloy steel made, with long life.

6.All the machinery and electrical devices are protected in accordance with the European CE standard.

Waste Wood MDF Plywood Board Wood Pallet Shredder Machine Application Areas:

single shaft shredder wood machine is mainly suitable for waste wood, pallet, tray, log, solid wood, tree roots, palms, trunk, branches, decorative sheets, building templates, wooden trays, wood footprints, wood risks, all kinds of waste wood and another shred.