Description:

Wood Plastic profile extrusion line adopts special design for screw and barrel, die head, and processing technique for wood-plastic products. It includes one step wook plastic thick plate equipment, one-step wood plastic profile equipment, one-step wood plastic decorative material equipment, etc.

The line applied to wood-plastic profile products for PE, PP, and PVC, mainly apply to the pallet, packing plate, floor, outdoor decorating materials, etc. Wood powder and plant fiber addition volume very high (Max. can be reached 50-75%).

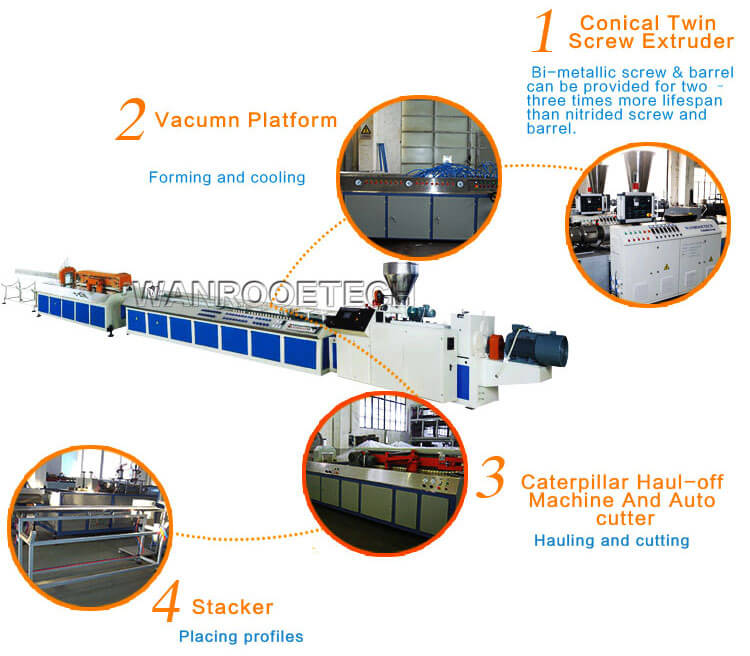

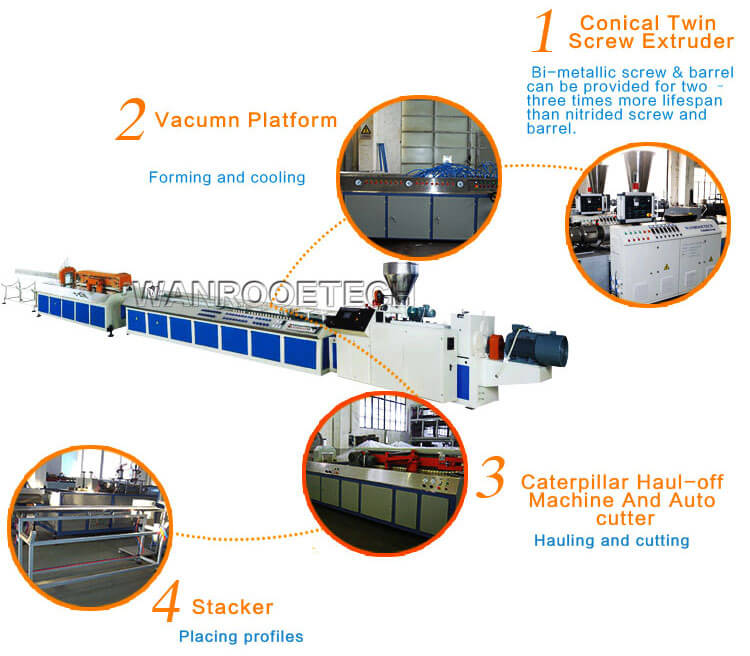

WPC extrusion line working process:

100% recycled PP, PE,etc+wood powder ( from wood dust, rice husk, wheat straw, etc)+ additives → mixing → granulating → conical twin-screw extruder → profile extrusion die → profile molds→ vacuum calibration platform →(haul-off machine) → cutter →stacker → finished product → surface finish processing, like embossing, sanding, brushing, etc

WPC profiles extrusion line consist of the following machinery:

1.material mixer machine

2.wood+HDPE granule making machine

3.WPC decking profiles extrusion line

4.sanding machine, brushing machine and embossing machine

5.crusher machine

Features:

Haul-off machine adopts special lifting technic, and works stable, has good reliability and strong pull. Vacuum forming machine adopts special large vortex cooling system, which is easy to cool down and form to meet the needs of high-speed extrusion. Cutter speed is the same as hauling speed, adopt PLC controller, reasonable design, stable working, can cut automatically and equip with a dust recycling system. According to different molds, the vacuum forming table can be 4 meters, 6 meters, 8 meters or 11 meters.

Application Areas:

outdoor application: WPC hollow decking, WPC solid decking, WPC beam/joist/keel, WPC wall cladding panel, WPC bench/chair, WPC fence/railing, upright post/pillar, WPC pavilion, WPC roof profiles, etc.

Indoor application: door window profiles, furniture decorative profiles, foaming profiles, etc.