PVC UPVC Profile Extrusion Machine Description:

This PVC Profile production line is my company to absorb the international technology, adopt efficient conical twin screw extruder, vacuum calibrating process, used to produce PVC doors and Windows profiles, window sill board, wall hangs Taiwan, decorative plate profile extrusion.

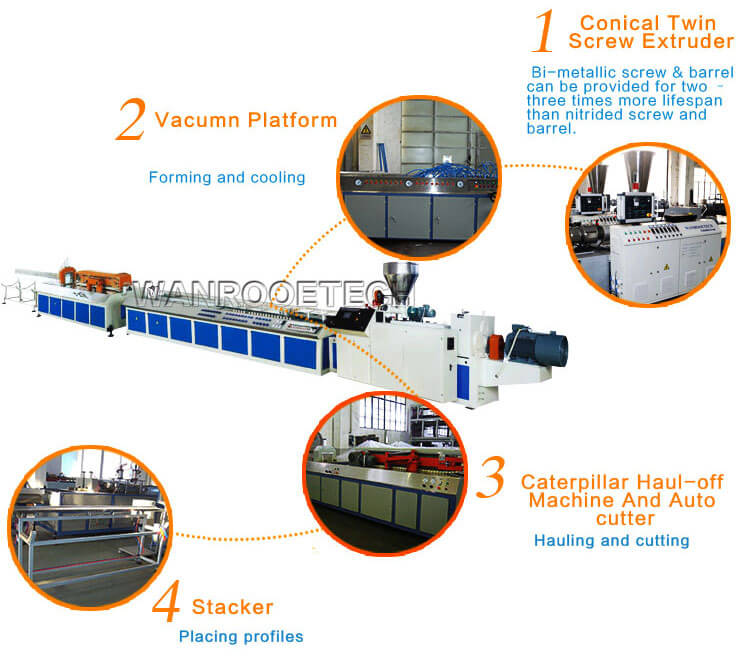

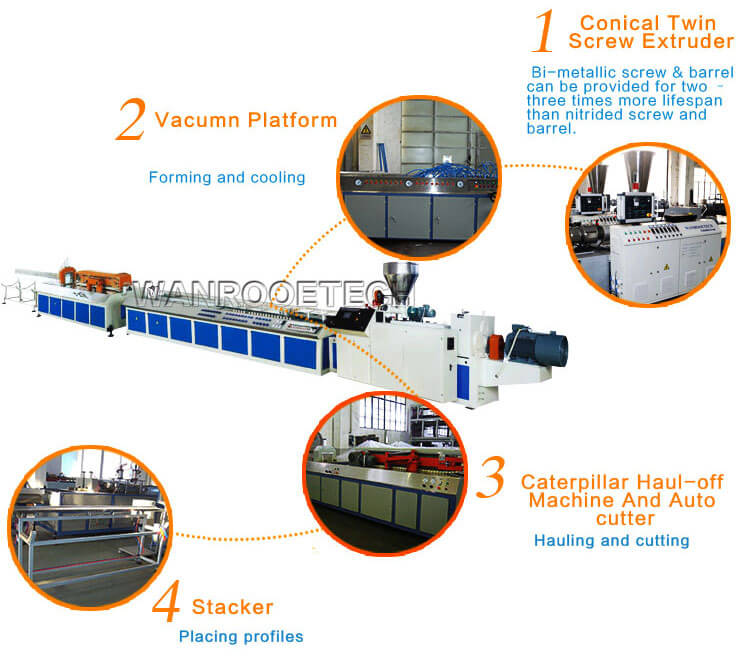

PVC plastic profile production line mainly PVC, UPVC as raw materials, production of various kinds of plastic doors and Windows profiles (plastic profiles, decorative profiles, etc. For different sectional surfaces and molds, twin parallel(conical)screws extruder of different specifications can be chosen together with the corresponding vacuum calibrating table,haul-off unit, cutting unit, tilter, etc. The capacity of the mainframe can be optionally chosen from 60-700kgs/hour. The haul-off unit has applied the unique lift technique of our co. Its work is stable, its reliability is good, its pulling force is large. Vacuum setting has applied special enlarged vortex cooling system which is good for cooling and calibrating so as to meet the demand for high speed extruding. Movement speed and drawing speed of cutting machines keep synchronous. All movements are controlled by imported PLC,the design is reasonable,the operation is stable. It can conduct automatic cutting with a fixed length.

PVC UPVC Profile Extrusion Machine Components:

PVC UPVC Profile Extrusion Machine Applications:

PVC plastic profile production line can produce push-pull series, 60 (60 second rail frame, 60 in the open, in 60's, 60 six windows, 60 single pressure, etc.), the 80 series (80, 80 bright pretty, 80 lightbox stand, 80), 88 series, and their respective by the series of PVC - U profiles; PVC plastic profile production line is suitable for production of push-pull window, Windows and Casement Windows, fixed Windows, etc. PVC Windows and doors profiles do not erode by any acid drugs, don't affect by waste gas and salt. Imported evolutionary agent, add UV absorber materials, in - between 30 to 70 degrees of the scorching sun, rain, dry and wet change does not change color, not aging, not brittle. Doors and Windows designed with the waterproof board, drain slots, rainwater can be completely insulated from outside, and window of model steel door is absolutely fine material, fire combustion, combustion, is your ideal choice.

PVC UPVC Profile Extrusion Machine Feature:

Intelligent control system: equipped with Siemens/Omron PLC integrated control platform, supporting precise control of multiple temperature zones and adaptive matching of extrusion speed, real-time collection and analysis of production data, and a 40% increase in process stability.

High reliability electrical configuration: The entire series adopts international first-line brand components such as ABB frequency converters and Siemens low-voltage electrical appliances. The critical circuits are equipped with double insulation protection, and the comprehensive failure rate of the equipment is less than 0.3%.

Multiple security protections:

The motor is equipped with ABB intelligent overload protection module, which can monitor current fluctuations in real time and automatically cut off power

The extrusion module is equipped with an Omron temperature anomaly warning system, which triggers an interlock shutdown when the temperature exceeds 10 ℃

Efficient finished product processing: Integrated online PE protective film winding device, using servo motor driven tension control system, achieving uniform coating of 0.1mm on the surface of profiles, and improving packaging efficiency by three times compared to traditional processes.

PVC UPVC Profile Extrusion Machine Application Areas:

PVC /WPC Profile Extrusion Line can produce all kinds of profiles, for example, window, door and door frame, PVC ceiling panels, pallet, cladding of outdoor wall, facility of outside park, floor, etc.