Plastic Bucket Hollow Barrel Crusher Description:

The plastic barrel crusher machine is used to crush the waste hdpe plastic barrels and containers for recycling.It can be used for processing water bottles, juice bottles, coka bottles, oil bottles, shampoo bottles, detergent bottles, plastic drums,etc. By the heavy duty plastic crusher, the plastic barrels are processed into flakes with indicated sizes for deep processing such as washing and pelletizing.

The plastic barrel crusher machine is manufactured with Germany technology, It has heavy structure and good performance for steady working and long life. It usually consists of feeding hopper, crushing chamber with stationary blades, rotor with rotary blades, drive motor, hydraulic units for openning hopper and screen change, safty switches and machine frame.

Plastic barrel crusher machine is a key machine in the waste plastic barrel and container crushing washing drying recycling industry, It must have excellent performance to ensure the high working efficiency.

Plastic Bucket Hollow Barrel Crusher Components:

|  |

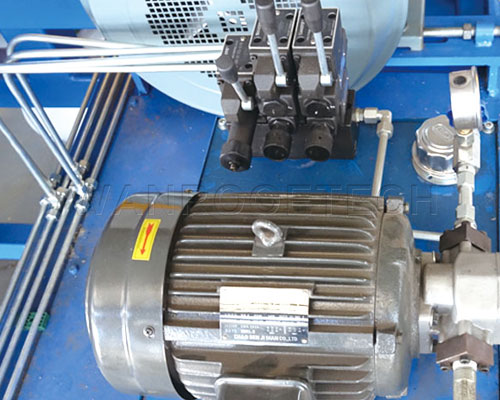

Hydraulic Connector Oil link device is installed for each machine to keep the orderliness and smooth of oil pipes. | Rotor Special“L" design rotor help the machine achieve the excellent grinding result saving the energy and reducing the noise. |

|  |

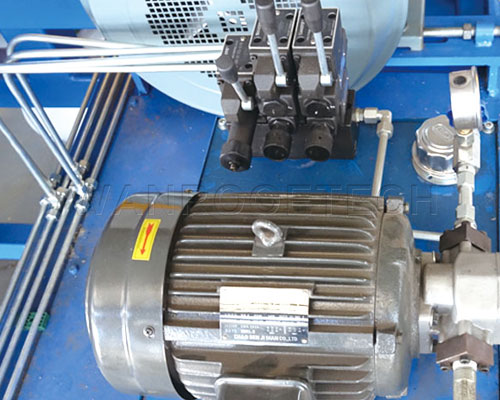

Screen Special material assures the long-life abrasion resistance of the screen.Well-proportioned high rate holes much improve the machine output. | Motor Overload Protector Equipped with electrical current relay, motor overload protector and other multiple safety devices. |

|  |

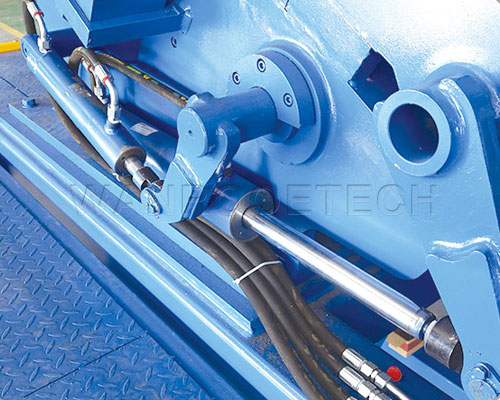

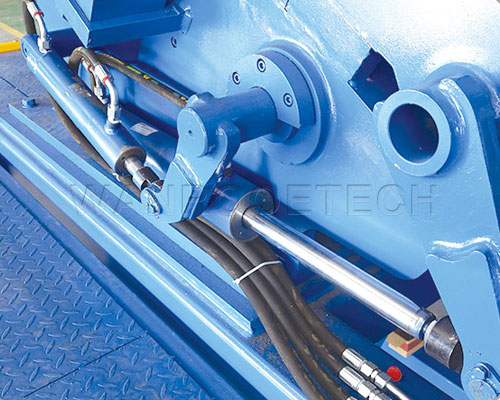

Hydraulic Cylinder Hydraulic device makes opening the chamber and screen much easier. | Metal Detector(Optional) Metal detector can be combined with belt conveyor, and can interlock with control system, to warn and stop the system, in case that metal is found in feeding. |

|  |

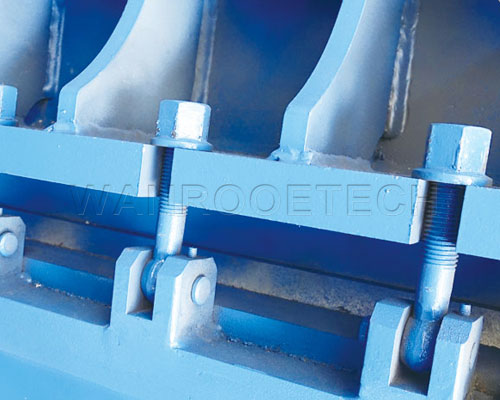

Hydraulic Equipment The hydraulic equipment can control the hydraulic cover opening of the crusher room, which makes the inspection and maintenance of the crusher room and the replacement of tools more convenient and fast. | Cutting Chamber lts' easy to open the full chamber, Loosen the nut, the chamber can be open within short time. |

|  |

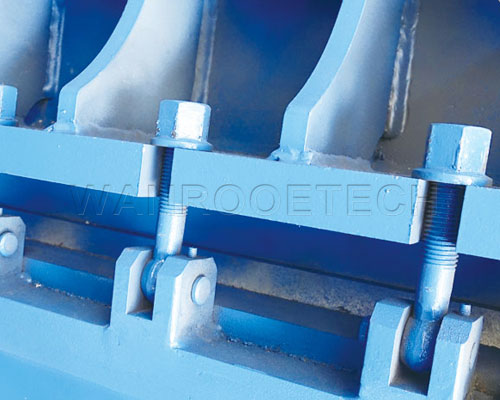

Screen Locked Device Simply design help convenient operation and reduce much time to replace the screen. | Shock Absorber Foot Foot with shock absorber to reduce vibration and eliminate noise. |

Plastic Bucket Hollow Barrel Crusher Feature:

Strong welded construction from heavy gauge steel plate.

Inclined, split cutting chamber design.

Oversized, outboard spherical rotor bearings – prevents bearing damage due to product migration.

Precision machined rotors (Forward set V-Rotor as standard).

Manual, electric and hydraulic chamber opening mechanisms - quick access to the cutting chamber for maintenance and machine clean downs.

Replaceable wear plates at either end of the rotor shaft.

Stand Alone Electrical Control Panel - using quality Schneider components and Siemens PLC’s.

Tested, Approved and Certified to the applicable CE safety standards.

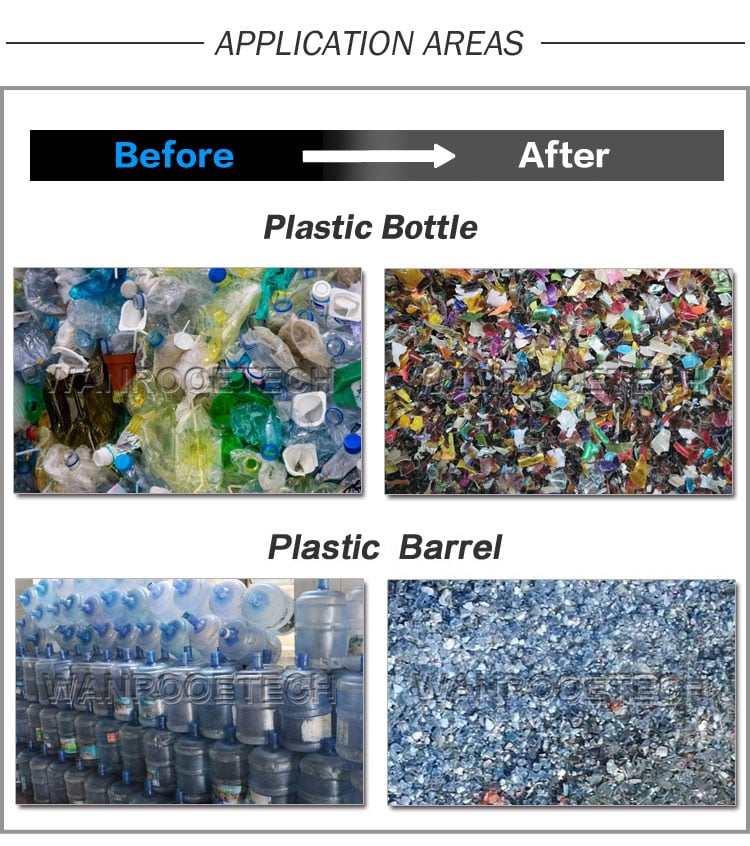

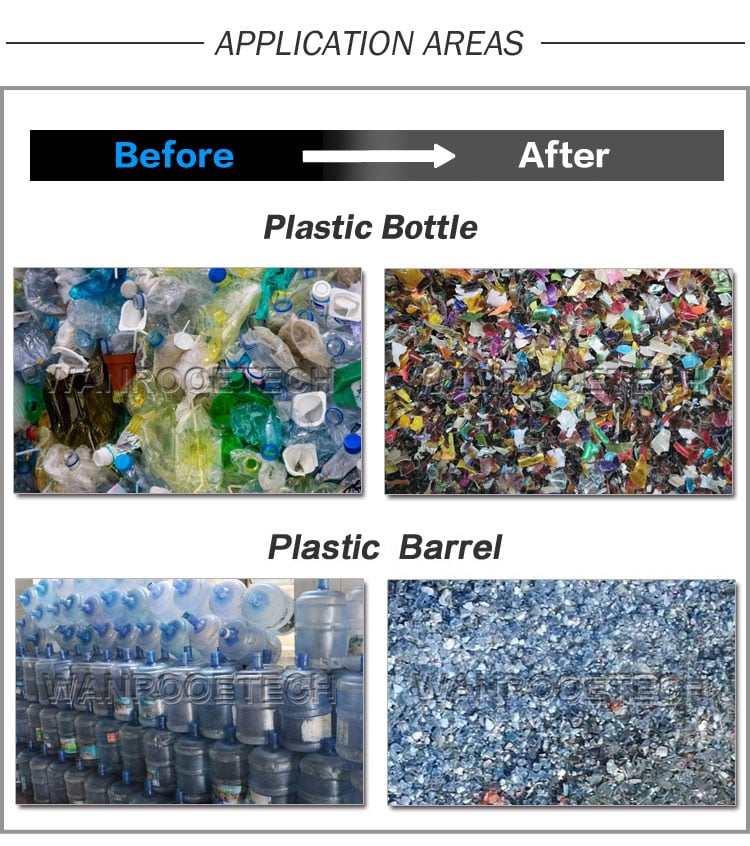

Plastic Bucket Hollow Barrel Crusher Application Areas:

Plastic bucket hollow barrel crusher is suitable for the material which has a big shape, high-strength, and massive capacity. For example, PET bottles, PC bottles, plastic bottles, plastic Barrel, plastic Drum, soft drink bottles, water and salad dressing bottles,peanut butter can, jam jars can, ice cream cone lids, and so on.