Waste Printed Circuit Board (PCB) Recycling Machine Description:

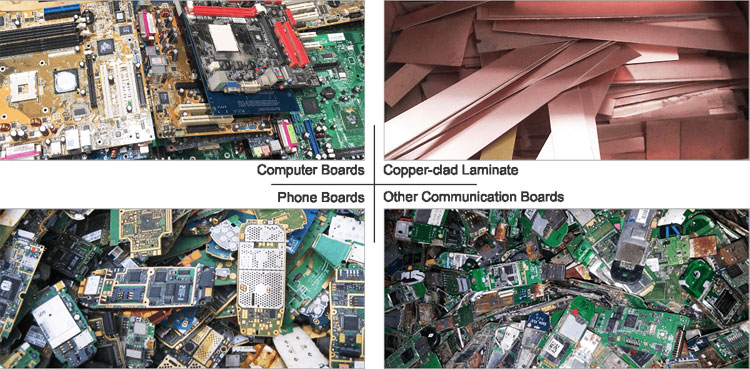

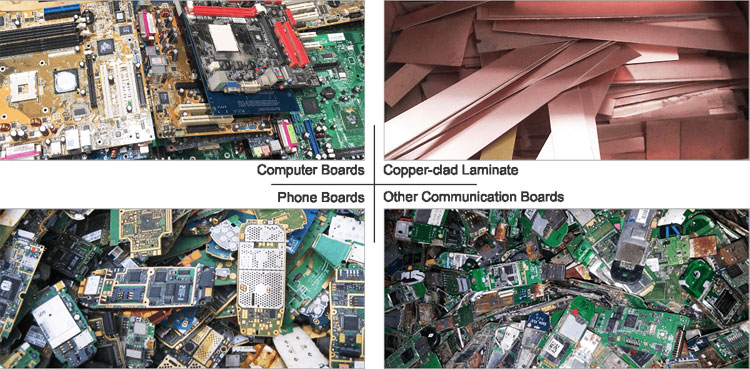

E-waste PCB recycling plant is used to recycle all kinds of printed circuit boards, such as computer boards, cell phone boards, TV boards, copper-clad laminate, and other household appliances, and the separation of leftover material of the mixed metal and nonmetal materials.

With the PLC control system, it could make the PCB recycling machine fully automatic with stable performance, easy to operate. And the PCB recycling machine is designed with an integrated type compact structure that could save land occupy size and easy to install. Further with the on-the-spot installation, commissioning and operation training service, would avoid your trouble on installation and operation. During the PCB recycling process, PCB would be firstly shredded or crushed, then sieved by rotatory vibrating screen and separated through air separation and electrostatic separation, which could achieve the recovery rate to 99.9%.

Waste Printed Circuit Board (PCB) Recycling Machine Application Areas:

Waste Printed Circuit Board (PCB) Recycling Machine is mainly used in the field of electronic waste disposal, efficiently separating metal and non-metal materials in waste PCB, realizing resource recycling and reuse, reducing environmental pollution and promoting sustainable development. Its technical advantages are high efficiency, environmental protection and high automation, widely used in circuit board manufacturing and many industrial fields.

Waste Printed Circuit Board (PCB) Recycling Plant Process flow:

Waste PCB→PCB dismantling machine→double shaft shredder→crushing machine→plastic grinding machine→air separator→electrostatic separator→pulse dust collector→metal and resin powder

1. PCB dismantling machine: Printed circuit board (PCB) dismantling machine disconnects the electronic components from the circuit board to get the electronic components, tin and the motherboard. It is mainly used as special equipment for dismantling electronic components.

2. Shredder: Waste PCB board shredded PCB scrap by double shaft shredder machine.

3. Crusher: The crusher the printed circuit board into a particle size of about 13 mm.

4. Pulverizer: The PCB scrap is grinding into powder by plastic grinding machine, so as to achieve the separation of lumpy materials into copper and plastic powder.

5. Airflow separator: Different physical reactions produced by the proportion of the material under the same airflow are separated from copper and plastic.

6. Electrostatic separator: Through the effect of static adsorption, the insulation and non -insulation are separated, and the separation of copper and plastic.

7. Pulse dust collector: The whole process is undersealed structure with an advanced pulse dust collector, which could ensure no dust fly around during the operation.

Waste Printed Circuit Board (PCB) Recycling Plant Components:

Waste Printed Circuit Board (PCB) Recycling Plant Technical Features:

1. Suitable structure and layout, stable performance and recycling water is used to control temperature and reduce noise in the grinder;

2. PLC system makes it easier to control the whole line, the negative pressure feeding system prevents the dust from running out;

3. Feedback system makes the grind much more effective;

4. The separation rate of air separator can reach 97% and the separation rate of pulse dust cleaning device can reach 99%;

5. Electrostatic separator makes the higher and quicker separation, moreover gets more non-ferrous metal;

6. With the magnetic separator, the iron can be separated from other metals.

What's In PCB That Could Be Recycled?

From the research for normal PCB boards, in which the percentages of the electronic components, baseboard, and soldering tin are 58%, 37%, and 5% separately. And for every one-ton baseboard, includes about 40% metal materials and 60% nonmetals, which contain almost all the common elements in the periodic table. By estimate, 1 ton computer circuit boards, contains 0.5kg gold, 130kg copper, 10kg iron, 60kg Plumbum, 40kg tin, 36kg nickel, 40kg antimony, and some other rare precious metals, like platinum, palladium, etc.