Application Areas:

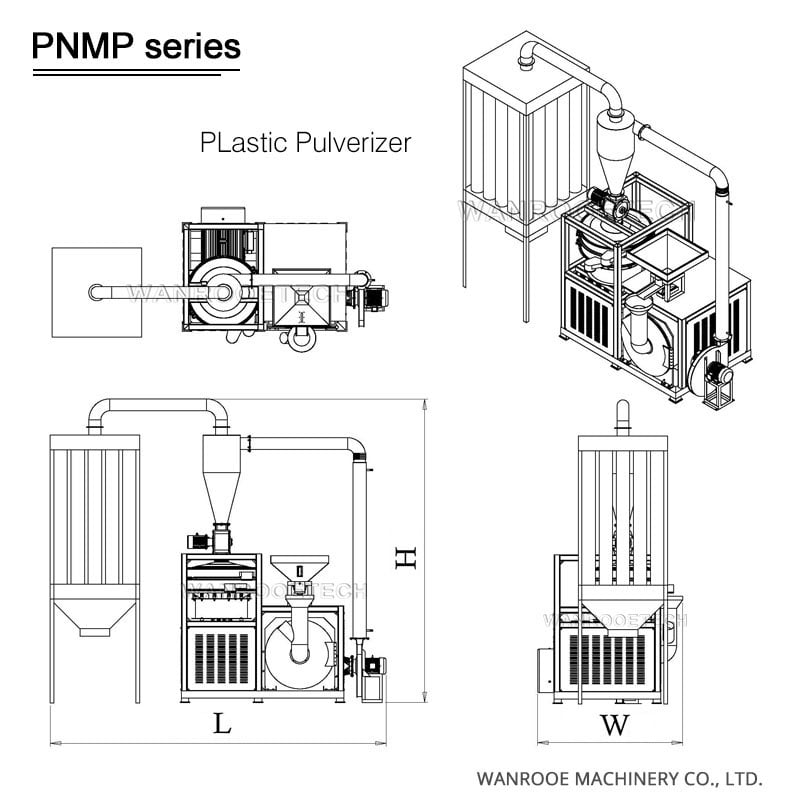

Automatic multifunctional PCB pulverizer machine is a series of disc type plastic mill. PCB pulverizer machine is used for the third stage crush. It has the characteristics of high production and low energy consumption. Waste PCB circuit board pulverizer mill machine is used for powder processing of polyethylene PE, polyvinyl chloride PVC, polypropylene PP, polystyrene PS, ABS, nylon, EVA, PET and other materials. It is the supporting equipment in the recycling plant of the waste circuit board and the aluminum plastic separation, mainly for grinding circuit boards or aluminum-plastic materials to be powdery, which provides convenience for sorting.

Description:

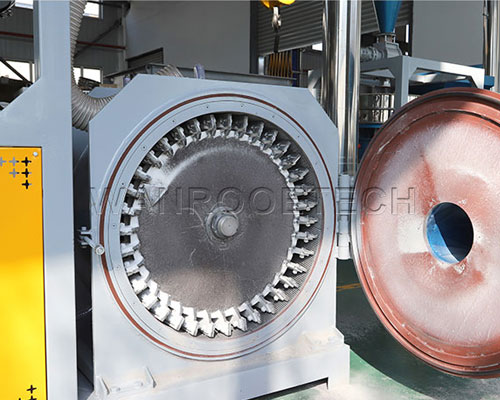

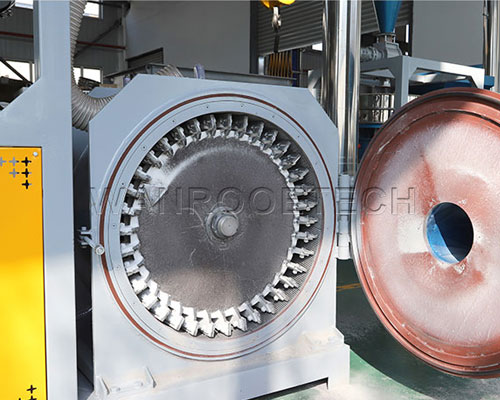

PCB Pulverizer mill is chiefly designed to grind PCB waste. The pulverizer uses turbo type blade. The static blade and rotary blade could be adjusted, thus you can get different size of PVC powder with one grinder. High output, low energy consumption and long lifespan attract many customers around the world. It can be used for PVC plastic from PVC pipe/profile/soft sheet/bottle/card from low to moderate hardness PVC.

The output of our PNMP pulverizer can reach 100-900kg/h (15-100mesh).

Components:

|

|

Conveyor belt feeding Used to load grinding PVC flake into pulverizer chamber by belt convey, The top of roller on belt conveyor made by magnetic roller which can remove any ferrous material from Plastic flake; It can protect the milling blade and increase the purity level of final plastic powder, the material is sent to the vibrating screen by vibration | PVC Pulverizer Disc Turbo-type pulverizer disc, Widely used for recycling PVC, such as PVC pipe, PVC profile, PVC sheets, SPC floor |

|  |

Pulverizer Blade Rotating and fixed blades, D2 or SKD-11 material, wear-resistant.The number of blades varies depending on the device model. | Conveying Pipe All 304 stainless steel, durable.Non-rusting, non-sticking powder.Double layer pipeline, water supply in the middle layer. |

|  |

Vibrating Screen Installation of screen according to the grinding mesh, continuous production, automatic classification and screening, easy to replace. | Intelligent Control Can be adjusted according to the actual situation simple operation, saving time and effort |

|  |

Bags Type Dust Catcher Smaller footprint, lower price, can reduce the workshop dust, customers with higher requirements for environmental protection can choose pulse dust catcher. | Pulse Dust Collecter(Optional) Collect dust from products during the grinding process to prevent pollution. |

Technical Features:

1. PNMP Pulverizer can easy to grind all kinds Hard & Soft PVC into powder.

2. The dust collector is added to effectively reduce dust pollution.

3. The discharging of the main fan reduces labors intensity of operating workers.

4. The door cover of the host can be opened for convenience of maintenance and replacement of cutters.

5. The mill use the water and wind double cooling system ,Prevent bearing and other parts from overheating.

6. The powder mesh is adjustable(15-100mesh).

7. Easy installation and maintenance, just open the door to clean up.

8. Well-known brand accessories, such as SKF bearings and Siemens motors, can work for a long time, saving the trouble of changing accessories frequently.

9. With a wide range of optional accessories, professional solutions can be developed based on the customer's budget and processing requirements.