Industrial Wood Tray Pallet Shredder Recycling Machine Application Areas:

Wood shredder machines are suitable for handling a wide range of wood waste materials. such as MDF plywood board, chipboard, OSB, hardwood, softwood, veneers (mixed with wood), cardboards (mixed with wood), paper, logs, wood pallets, bark, wood timber, wood tray, solid timber waste, demolition wood, wooden floor, wood pallet, wood sofa, wood furniture, wooden box, MDF plywood board, wood board, etc.

Industrial Wood Tray Pallet Shredder Recycling Machine Description:

Waste wood shredder machine with loading hoppers, equipped with high-quality cutters with low rotation speed for lower energy consumption and noise reduction. It incorporates two counter-rotating shafts that intermesh with each other(2 shafts with sharp elements constituted by sharp-corners disks provided with hooks; Every hook has the task to hook the product and drive it by the action of the two counter-rotating shafts). The material is powerfully torn and shredded by the talons of the cuttings discs. Specially designed rotor makes the shredder be extremely wearing resistant.

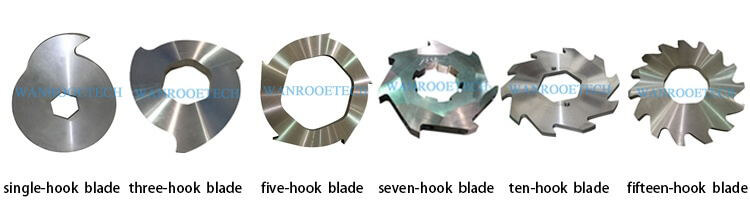

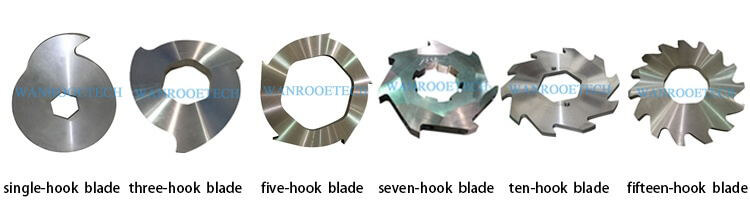

Double Shaft Shredder Blades(According to different materials choose different blades ):

Industrial Wood Tray Pallet Shredder Recycling Machine Components:

|

|

Shredder Chassis The whole chassis is made of welded steel plate and finely machined by CNC gantry milling, which has high bearing capacity, high impact resistance and more stable quality. | Shredder Spindle The shredder spindle is made of high alloy, forged and heat-treated and tempered as a whole, and then machined into hexagonal, octagonal and spline form by CNC gantry milling after fine turning, with long service life. |

|  |

Shredder Blade The shredder blade is made of special steel, forged, faded, refined, vacuum heat treatment, computerized wire cutting, CNC grinding machine processing. | Segmented Blades The segmented blade design can greatly reduce the blade changing time and cost. The blade comprises of the blade holder, and two types of blade segments, with and without hooks. Worn blade segments can quickly and easily be removed and replaced by simply removing the securing screws. |

|  |

Shock Absorber Polyurethane shockproof design can effectively remove the vibration generated during the operation of the equipment and protect the reducer and bearing from the vibration. | Gearbox

Integrated box design, stronger mechanism, stronger output shaft and bearing design, longer service life and greater torque.Flexible cooling mode to meet the requirements of thermal power. At the same time, the output shaft adopts double oil seal design, which greatly reduces the risk of oil leakage. |

|  |

Brand Motor The motor adopts Siemens, Wanan and other domestic brands of pure copper motor, with stable and reliable quality, and can be customized according to requirements. |

Electronic Control The whole model adopts frequency conversion control and conforms to international standards such as CE/CSA. |

Industrial Wood Tray Pallet Shredder Recycling MachineTechnical Features:

Slow Speed High Torque Shredding Principle

Low Dust and Low Noise Operation and Rugged Low Maintenance Design.

Shock absorbing shaft couplings between gearboxes and blade shafts reduces operational stress.

High Strength Cutters and Spacers manufactured from high quality, heat treated steel alloys are suitable for shredding tough materials.

Individual Cleaning Fingers mounted to the chamber sidewalls ensure quick discharge of shredded materials.

Modular Chamber Design with split endplates and bearing housings enables quick access to key components.

Advanced Adjustable Sealing System for the bearings.

Stand Alone Electrical Control Panel with Siemens PLC Control System.

Tested, Approved and Certified to the applicable CE safety standards.