What is a battery shredder?

Battery shredders and shredding systems are specifically designed for your application, whether you recycle electric car batteries, lithium ion batteries, absolyte batteries, alkaline batteries or lead acid batteries, just to name a few.

Battery shredders utilize a low speed, high torque, twin shaft shredder as the primary shredder prior to further processing. Lithium-ion batteries, as well as other batteries, contain cobalt, nickel, copper and various precious metals that, if separated, can be recycled and reused.

Battery shredders incorporate a constant water bath to prevent fires, along with a chemical-based secondary fire suppression program. Most batteries need to be discharged before they can be recycled. The physical process usually includes pretreatment and direct recovery of electrode material.

Principle of lithium battery shredder

Used lithium batteries are poured into the feed bin of the shredder. At this point, the pushing device squeezes the material downward to speed up the crushing speed of the material and improve the crushing efficiency. The lithium battery is crushed into small pieces by the main crusher and output through the discharge hopper. As lithium batteries are flammable and explosive items, in order to ensure the safe operation of the whole process, it is necessary to discharge the lithium batteries before shredding.

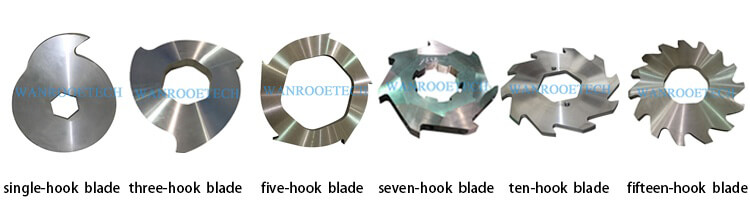

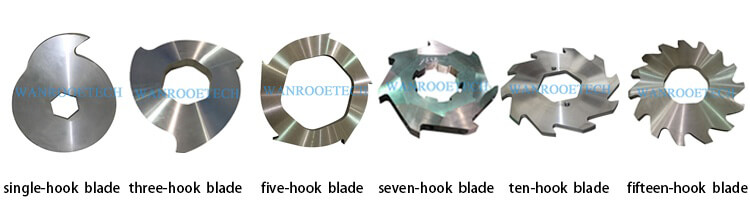

Double Shaft Shredder Blades:

Industrial Lithium Battery Shredder Recycling Machine Components:

|

|

Shredder Chassis The whole chassis is made of welded steel plate and finely machined by CNC gantry milling, which has high bearing capacity, high impact resistance and more stable quality. | Shredder Spindle The shredder spindle is made of high alloy, forged and heat-treated and tempered as a whole, and then machined into hexagonal, octagonal and spline form by CNC gantry milling after fine turning, with long service life. |

|  |

Shredder Blade The shredder blade is made of special steel, forged, faded, refined, vacuum heat treatment, computerized wire cutting, CNC grinding machine processing. | Segmented Blades The segmented blade design can greatly reduce the blade changing time and cost. The blade comprises of the blade holder, and two types of blade segments, with and without hooks. Worn blade segments can quickly and easily be removed and replaced by simply removing the securing screws. |

|  |

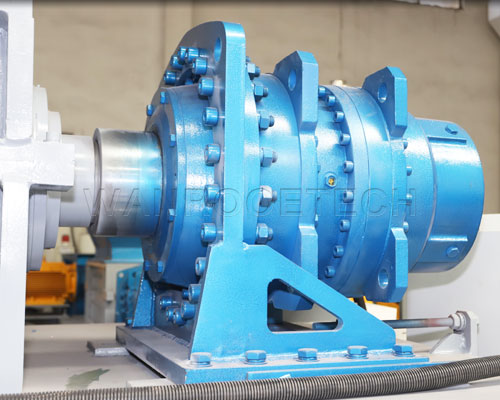

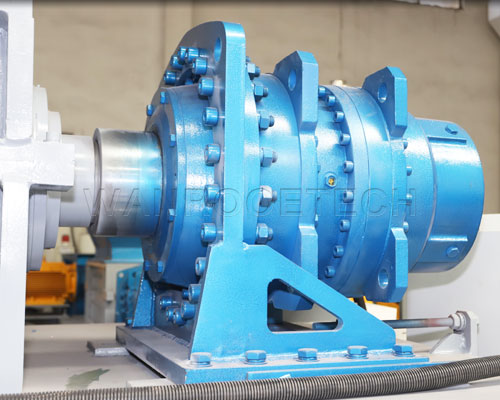

Motor The motor adopts Siemens, Wanan and other domestic brands of pure copper motor, with stable and reliable quality, and can be customized according to requirements. | Planetary Reducer The reducer chassis adopts welded box, helical gear, planetary gear transmission, with small volume, low noise, high torque and other characteristics, higher transmission efficiency. |

Why do we need to recycle batteries?

With the development of modern communication industry, batteries are used as the power of many products, such as radios, watches, remote controls, toys, cell phones, laptops, etc. The heavy metals inside the battery react with the electrolyte to produce energy. Waste batteries contain a large amount of heavy metals and electrolytes such as waste acids and alkalis. If waste batteries are discarded at random, they will destroy our water sources and erode our plants and land. Therefore, all batteries need to be recycled, not only to protect the environment, but also to reuse the useful components inside the batteries and save resources.

The purpose of recycling used batteries is to prevent harmful substances from polluting our environment and to create business and employment opportunities for more people. Waste battery shredder is a popular recycling machine in waste battery recycling.

Battery Shredding System

At present, the cathode materials used to produce lithium-ion batteries mainly include lithium cobaltate, lithium manganate, lithium nickel cobalt manganate ternary materials and lithium ferrous phosphate. Therefore, used lithium-ion batteries contain more cobalt (Co), lithium (Li), nickel (Ni), manganese (Mn), copper (Cu), iron (Fe) and other metal resources.

wanrooe developed the recycling of used batteries because it has a huge economic and ecological value. Battery shredder combined with metal separation.

Advantages of battery shredder

The battery shredder is designed with two shafts, which can load a large number of discharged batteries. The low speed and high torque working principle is very suitable for shredding different sizes of lithium batteries.

The reverse shearing force of the cutter can cut the lithium battery into smaller pieces, which is very convenient for subsequent processing.

Low speed, high torque, high shearing force, good shredding effect, low noise and good stability.

Some people may claim that the knives of battery shredder are not durable. However, our special alloy hardened blades can shred up to 3 times longer.

Versatile and can also be used for shredding lithium batteries, circuit boards, mice and other electronic waste.