Car Oil Filter Shredder Application Areas:

Oil filter shredder is a machine for reducing the size of filter, shredding the filter into specific size. Filter shredders come in many different variations and sizes. They can also be used for shredding another kind of solid waste. Some examples of materials that are commonly shredded are tires, metals, car wrecks, wood, plastics, and garbage.

Different types of oil filters are used in motor vehicles to clean the oil. The oil filters have specific life and thus require replacement. As a result, millions of oil filters are replaced in India and abroad and generating a huge quantity of hazardous waste. WANROOETECH developed PNSS Double Shaft Shredders, especially suitable for the processing and recycling of oil filters in the most profitable manner. After shredding, the separated metals are sold in the scrap for further recycling and use, while the separated paper waste is used to make reduced-derived fuel.

Car Oil Filter Shredder Description:

The oil filters mounted on cars, trucks, and tractors, if shredded and properly processed, can return 97% of the materials.

The components which can be recovered are oil, paper, plastics, ferrous materials and not.

The process foresees the following steps:

1. Loading operation;

2. Selection of the input material;

3. Volume reduction shredding

4. Controlled size shredding;

5. Removal of oil residue from the materials;

6. Separation of ferrous materials, non-ferrous, paper, and plastic.

7. WANROOETECH offers comprehensive plants for the processing of oil filters, including a two-shaft shredder for volume reduction stage and a three- or four-shaft shredder to get a homogenous size of the material before entering the centrifuge.

After centrifugation, a magnetic separator provides to remove the ferrous fraction before the final separation of the non-ferrous metals, paper, and plastic.

The metals recovered, ferrous and non are about half of the total material processed and will be suitable as secondary raw material, the used oil can be regenerated (100 kg of used oil returns approximately 65 kg of regenerated oil and 25% base of diesel fuel/bitumen, ref. C.O.O.U) whereas the recovered paper and plastics can be used for TDF production.

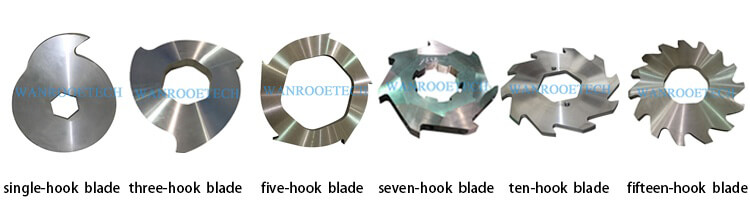

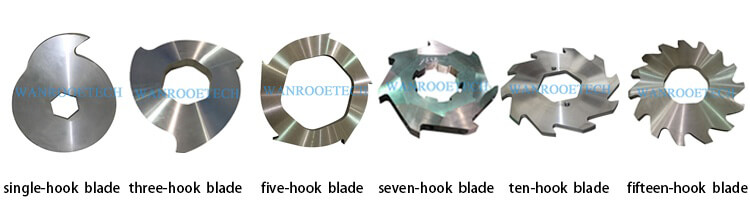

Double Shaft Shredder Blades(According to different materials choose different blades ):

Car Oil Filter Shredder Components:

|

|

Shredder Chassis

The whole chassis is made of welded steel plate and finely machined by CNC gantry milling, which has high bearing capacity, high impact resistance and more stable quality. | Shredder Spindle

The shredder spindle is made of high alloy, forged and heat-treated and tempered as a whole, and then machined into hexagonal, octagonal and spline form by CNC gantry milling after fine turning, with long service life. |

|  |

Shredder Blade

The shredder blade is made of special steel, forged, faded, refined, vacuum heat treatment, computerized wire cutting, CNC grinding machine processing. | Segmented Blades

The segmented blade design can greatly reduce the blade changing time and cost. The blade comprises of the blade holder, and two types of blade segments, with and without hooks. Worn blade segments can quickly and easily be removed and replaced by simply removing the securing screws. |

|  |

Motor The motor adopts Siemens, Wanan and other domestic brands of pure copper motor, with stable and reliable quality, and can be customized according to requirements. | Planetary Reducer

The reducer chassis adopts welded box, helical gear, planetary gear transmission, with small volume, low noise, high torque and other characteristics, higher transmission efficiency. |

Technical Features:

1. Our shredders can be employed as either a primary or secondary shredder and can be seen working anywhere from the waste management company to biofuel producers;

2. Dual shafted, slow-speed, high-torque waste shredder with hardened steel cutters;

3. The two cutting rotors powerfully grab the feed material, and no matter the feed material is a large piece of hard plastic or heavy tires, this machine can easily shred them into small pieces;

4. Double shaft shredder is able to process a number of different materials; shredder is designed with a powerful engine, long working length and aggressive input, Internal feeding volume bigger than traditional and common single shaft shredder machine and allow you using forklift truck to feed.

5. Heavy structure: the frame and structure of our shredders are made of high-thickness sheets and tubular. Blades are manufactured from high-quality steel, suitable for shredding tough materials and for extra long life;

6. Depending on the requirement, these discs (blades) are available in a wide range of quantities, qualities, and shapes with the new double-shaft shredder;

7. Any overloads caused by foreign material are sensed by the PLC controller and cause the shaft rotation to stop and reverse direction to clear the foreign matter, and then resume;

8. Cutters removal and replacement can be carried out safely and simply.

9. Our shredders Use a planetary reducer, not a traditional gearbox, and the planetary gearbox has the following advantages: High Efficiency, Greater Stability, Compact Size, Higher Torque Density, Cost-Effective Precision, High Radial Loads.

10. Cooler system(optional) can maintain the temperature for continuous operation.

Related Links:

How to recycling oil filfter?