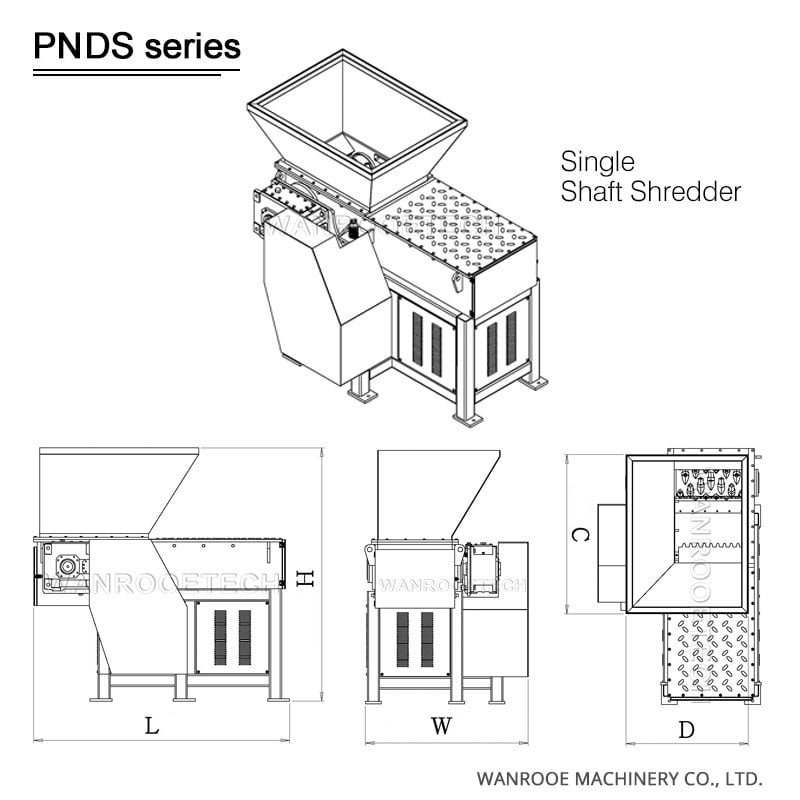

Waste Garbage Shredder Used Plastic Furniture Shredding Machine Description:

Waste Garbage Shredder Used Plastic Furniture Shredding Machine has been designed for a wide range of applications and industries such as pallets and big barrels in mind, house and general recycling, electronic waste, While it can be used for in house recycling in big volume blow moulding operations; additionally, it is also versatile enough to be used for general recycling in the plastic and wood industry. According to customers' requirements, the PNDS series shredder can work with WANROOETECH's crusher machine for the next step of size reduction.

This single shaft plastic shredder machine is newly designed especially for shredding various big solid materials, unmanageable materials, plastic containers and barrels, plastic film, plastic pipe, fiber and paper which the normal crusher can't handle.

The materials are pushed into the shredding chamber by hydraulic. Independent drive system and solid structure make the running stable.

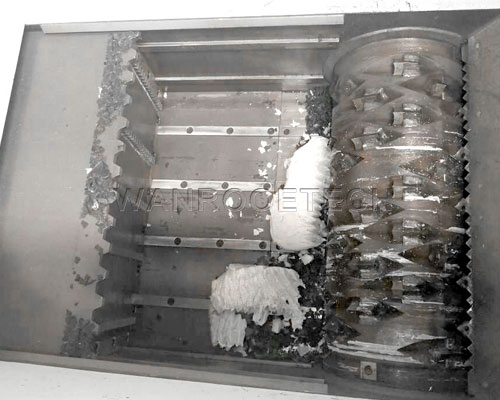

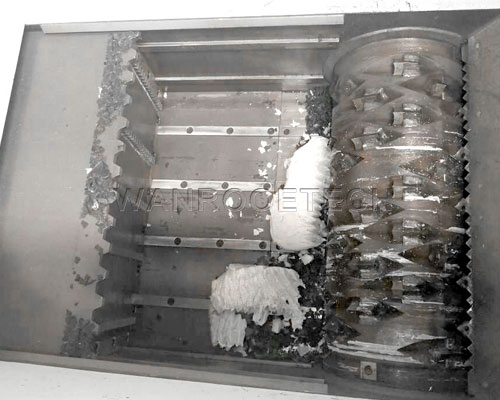

Single Shaft Shredder Blade:

Waste Garbage Shredder Used Plastic Furniture Shredding Machine Components:

|  |

Pusher System Reinforced baseplate can reduce the impact caused by material entering the cutting chamber. A dust collection device is equipped at the bottom of the pusher system to guarantee the long-term stable performance of internal components. | Heat treated rotor knives Special DC53 steel (hardened) four edges use before the replacement |

|  |

V-cutting rotor design with staggered cutter positioning | Wear Resistant Tungsten surface coating for abrasive applications |

|  |

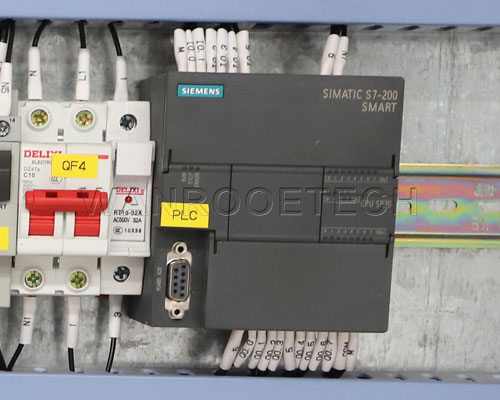

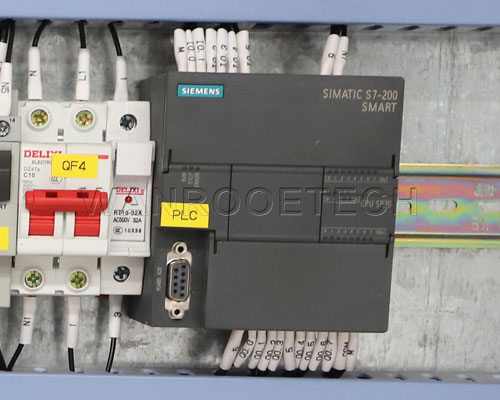

Control panel Equipped with independent and reliable electrical control panel like SIEMENS PLC control system, DELIXI contactor, SCHNEIDER Electric, etc. Manual & automatic operational modes to choose, quite flexible and safe.Motor overload protection.

| Screen Unit Wide range of screens with a variety of configurations and mesh sizes are replaceable based on customers' production requirements. The paper shredder will automatically stop while opening the screen unit to ensure operator safety. The screen is produced and mounted in sections, allow for easy maintenance. |

|  |

PLC control Making it easier for fault diagnosis and maintenance. | Hydraulic Station The pressure and rate of flow can be adjusted according to different materials. |

Waste Garbage Shredder Used Plastic Furniture Shredding Machine Features:

1) Precisely processed combined frame made of extra-thick plates; Lange-angle, hexagon prism of power slewing axis; Big hopper with big caliber for feeding big material

2) PLC control system with automatic overload protection and auto-reverse switch

3) Unique hydraulic pushing system accelerates the shredding speed, for light material particularly

4) Each dynamic blade has four cutting edges which enable reutilization after being abraded, by rotating 90 degree

5) Each fixed blade has two cutting edges which enable reutilization after being abraded, by rotating 180 degree

6) Quiet operation at low speed

7) Screen perforation is adjustable according to customers' requirement

8) The used plastic shredders can be adjusted according to customer-specific requirements for throughput volume, material to be processed, etc.

Waste Garbage Shredder Used Plastic Furniture Shredding Machine Application Areas:

The single shaft used plastic shredder machine is mainly used in all kinds of hollow or solid plastic material. The shredder machine is suitable for PE, PP, PET, ABS, PVC and engineering plastics.

Commonly Recycled Plastics Include:

ABS (Acrylonitrile butadiene styrene)、PVC (Polyvinyl chloride)、HDPE (High-density polyethylene)、LDPE (Low-density polyethylene)、PET (Polyethylene terephthalate)、PP (Polypropylene)、Epoxy、Purgings、Film、Big Bags、Bottles、Containers、Glass Fiber、Pipes、Ropes etc.