Recycling Wasted Fiberglass Reinforced Plastic FRP Shredding Machine Application Areas:

Fiberglass shredder is a machine that is used to shred fiberglass into small pieces. There are many types of fiberglass shredders with different capacities and output sizes. You can always find the most optimal fiberglass shredder according to your actual needs. Fiberglass shredder is widely used in fiberglass recycling. This machine can make the fiberglass be easily re-used in the following process.

Recycling Wasted Fiberglass Reinforced Plastic FRP Shredding Machine Description:

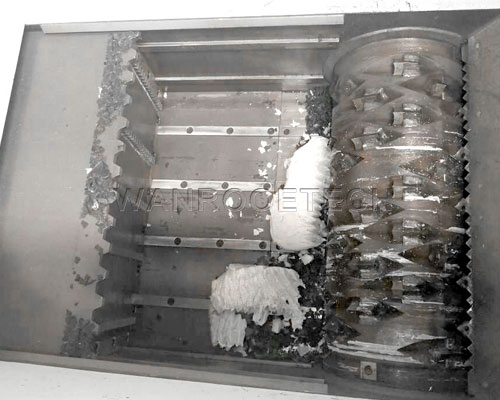

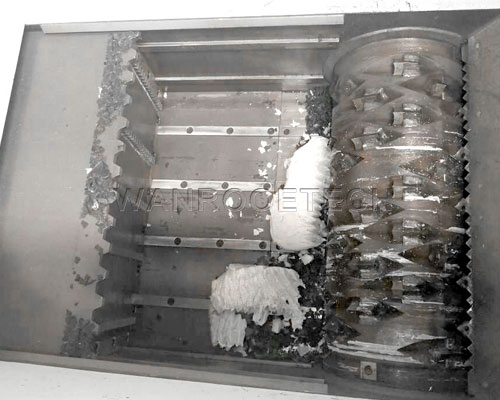

Fiberglass Single shaft shredder uses the interaction of movable cutter heads and fixed knives to tear, cut and extrude the material into small size. It can be available for shredding a wide range of materials including plastic, wood, rubber, and paper, etc. The cutter head is consists of basic shaft and pieces of quadrangle cutter. There are four edges which are easy to change. ‘V’ shaped rotary cutters are fixed on single shaft. The fixed cutter is mounted at an angle in adjacent to rotary cutter to achieve better cutting. The material is grabbed between ‘V’ shaped rotary cutters and fixed cutter shreds repeatedly. During the grinding process, the evenly cutting, saving of energy and reducing of noise are ensured by the installation of ‘V’ shape rotor knives. Also the knives are very easy to install and remove.

The materials are pushed into the shredding chamber by hydraulic. An independent drive system and solid structure make the running stably.

Fiberglass Shredder Blade:

How to recycle fiberglass?

Firstly we have to use the fiber glass shredder to shred the fiber glass waste. Due the diversity forms of fiber glass waste, we have to use the fiber glass shredder to make it uniformity. It is not only for convenient transport, but also for the convenience of the next recycling step. Then we send it to professional fiber glass recycling centers. In the recycling center, it will transform the pieces/powder of fiber glasses into brand new material that can take place of wood/aluminum to build picnic tables, fencing, sea walls and other items.

Recycling Wasted Fiberglass Reinforced Plastic FRP Shredding Machine Components:

|  |

Pusher System Reinforced baseplate can reduce the impact caused by material entering the cutting chamber. A dust collection device is equipped at the bottom of the pusher system to guarantee the long-term stable performance of internal components. | Heat treated rotor knives Special DC53 steel (hardened) four edges use before the replacement |

|  |

V-cutting rotor design with staggered cutter positioning |

Wear Resistant Tungsten surface coating for abrasive applications |

|  |

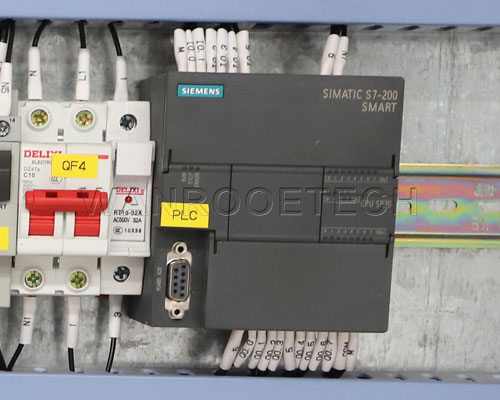

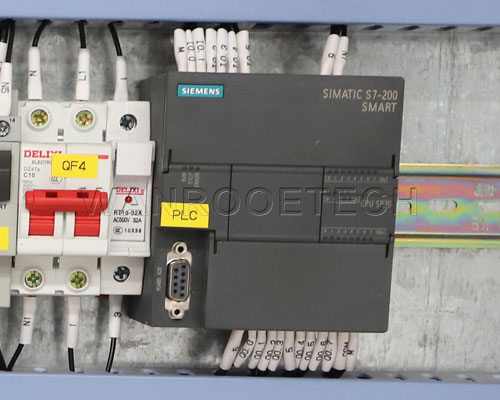

Control panel Equipped with independent and reliable electrical control panel like SIEMENS PLC control system, DELIXI contactor, SCHNEIDER Electric, etc.

Manual & automatic operational modes to choose, quite flexible and safe.Motor overload protection.

| Screen Unit Wide range of screens with a variety of configurations and mesh sizes are replaceable based on customers' production requirements. The paper shredder will automatically stop while opening the screen unit to ensure operator safety. The screen is produced and mounted in sections, allow for easy maintenance. |

|  |

PLC control Making it easier for fault diagnosis and maintenance. | Hydraulic Station The pressure and rate of flow can be adjusted according to different materials. |

Recycling Wasted Fiberglass Reinforced Plastic FRP Shredding Machine Features:

Design of external bearing is waterproof and dustproof, which prolong the service life of the bearing.

The blade uses cold working die steel, has good strength, high toughness, and high cutting performance.

The blade has four cutting edges, they can rotate 90° after wear and continue to use.

Hardened reducer has high transmission efficiency, strong bearing capacity, and low noise.

GL series single shaft shredding machine is controlled automatically by microcomputer (PLC), it has the function of starting, stopping, reversing and overloading automatic inversion control when.

The minimum material size of discharging is 20mm, each type of feed bucket can be provided according to the demand of the customer.