PE LLDPE LDPE Plastic Rotomolding Pulverizer Description:

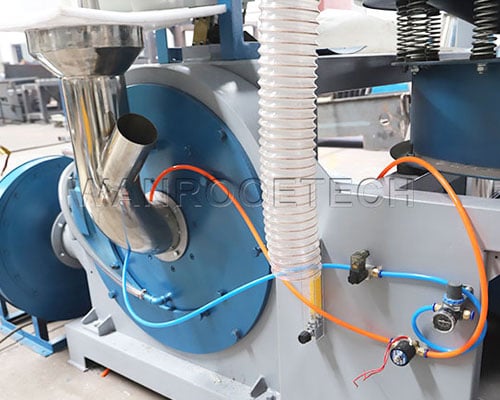

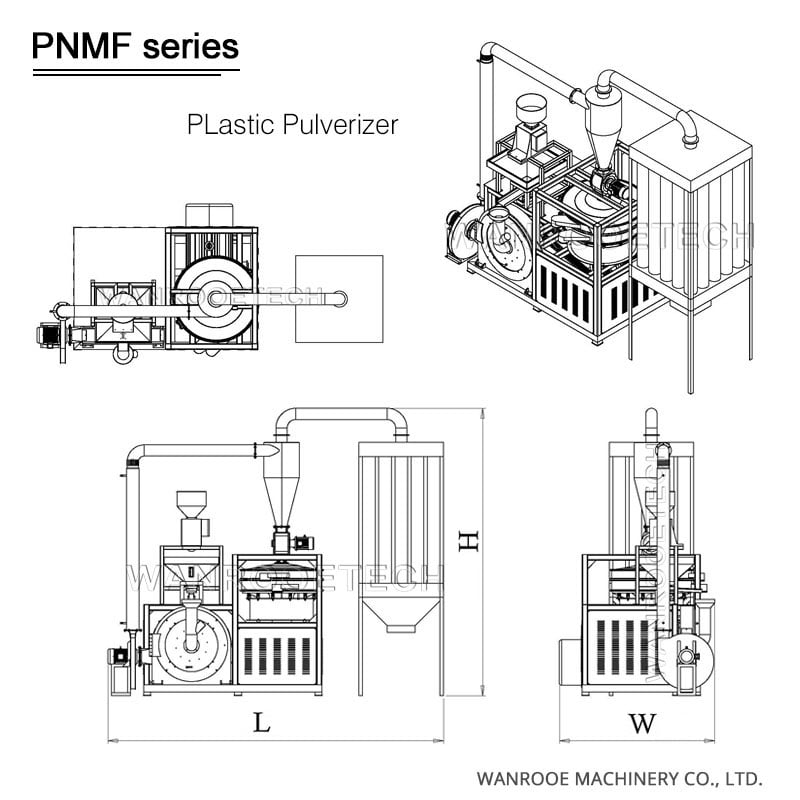

The PE LLDPE LDPE disc grinding pulverizer machine of the PNMF series is available with disc diameter from 300 to 800 mm. These plastic pulverizer machines are high speed, precision grinders for the processing of medium-hard, impact-resistant and friable materials. The material to be pulverized is introduced through the center of a vertically fixed grinding disc which is mounted concentrically with an identical high speed rotating disc. Centrifugal force carries the material through the grinding area and the resulting powder is collected with a blower and cyclone system. Depending on the application, the machines can be equipped with one-piece grinding discs or grinding segments.

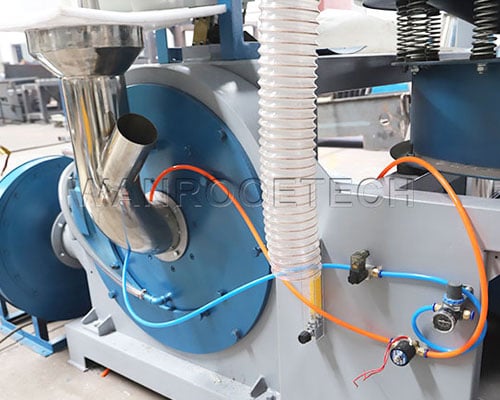

The plastic pulverizer machine is mainly composed of the electric motor, disc type blade, feeding fan, vibrating sieve, dust removing system, etc.

According to the customer's needs, you can choose some accessories, such as a converter, vacuum loader, screw loader, magnetic net, metal separator, chiller, pulse dust collector, metering and weighing packaging machine, etc.

PE LLDPE LDPE Plastic Rotomolding Pulverizer Application:

PNMF series PE LLDPE LDPE Plastic Rotomolding Pulverizers are intended to pulverize mid-hard, breakable to high impact plastics that need the ultimate material in powder form. Pulverizers are mainly used for PE, PP, PC, EVA. PS, PES other different types of plastics. The input material required for the pulverizer must be in a crushed form with a maximum size of 6-8 mm

Pulverizer is used in the plastic industry for Plastics Pulverizing Including PVC Recycling, Rotational Molding, Compounding and Master batching.

PE LLDPE LDPE Plastic Rotomolding Pulverizer Process:

The process is to load the powder into the mold and rotate it around two mutually perpendicular axes. Heated and evenly sintered on the inner wall of the mold into one, and then cooling can be obtained from the mold hollow products.

PE LLDPE LDPE Plastic Rotomolding Pulverizer blades:

Technical Features:

1. Advantages: full automation, unattended, fewer people, saving labor!

2. Dust-free, avoid dust interference workshop!

3. High yield, 2000-3000kg/h

4. HMI touch screen control system, one key start, fault alarm, fault diagnosis, PC monitoring!

5. Feeding system and powder collection system and mill system separation design.

6. Vacuum system automatically feeding, grinding, vacuum system automatically collects materials, the bin can be placed in a distant room or workshop!

7. More mills can also be integrated together!

Components:

|

|

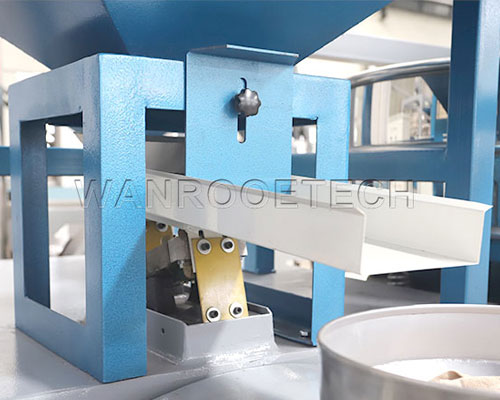

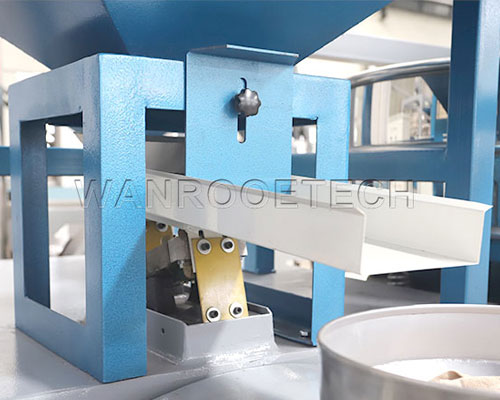

Vibratory Feeding The vibrator feeder is used to feed the material evenly into the mill, with strong magnetism, which can absorb the metal in the material and protect the mill disc. | Pulverizer Disc Pulverizer disc diameter 300-800mm, pulverizer machine fixed disc double layer, with cavity, through the water cooling. Pulverizer moving disc, atomized cooling. |

|  |

Whole Body Pulverizer Blade Hard force, working force is very large, can be customized according to the customer's material characteristics of different types of blades, standard configurations. | Segment Pulverizer Blade Segment pulverizer blade, after a long time use, only need to resharpen it, no need to replace the whole blade. A set of blades can be repaired 4-5 times, which reduces the operation cost of customers, and PNMF-600/800 can be equipped with split blades. |

|  |

Temperature Control The enhanced cooling device for automatically controlling the temperature includes a nozzle for spraying in cooling water, regulating control devices, solenoid valves, thermostats, an automatic control device and a material feeding switch. | Vibrating Screen Installation of screen according to the grinding mesh, continuous production, automatic classification and screening, easy to replace. |

|  |

Bags Type Dust Catcher Smaller footprint, lower price, can reduce the workshop dust, customers with higher requirements for environmental protection can choose pulse dust catcher. | Intelligent Control Can be adjusted according to the actual situation simple operation, save time and effort |

Application Areas:

The PNMF series automatic plastic mill is a disk-type plastic pulverizer, which has the advantages of high capacity and low-power, This machine can be used for powder processing of PE, HDPE, PP, PS, ABS, EVA, PET, nylon and other materials.

PNMF series plastic pulverizers can process powder sizes up to 20-120 mesh.