PNMF-600 Model Plastic Pulverizer Description:

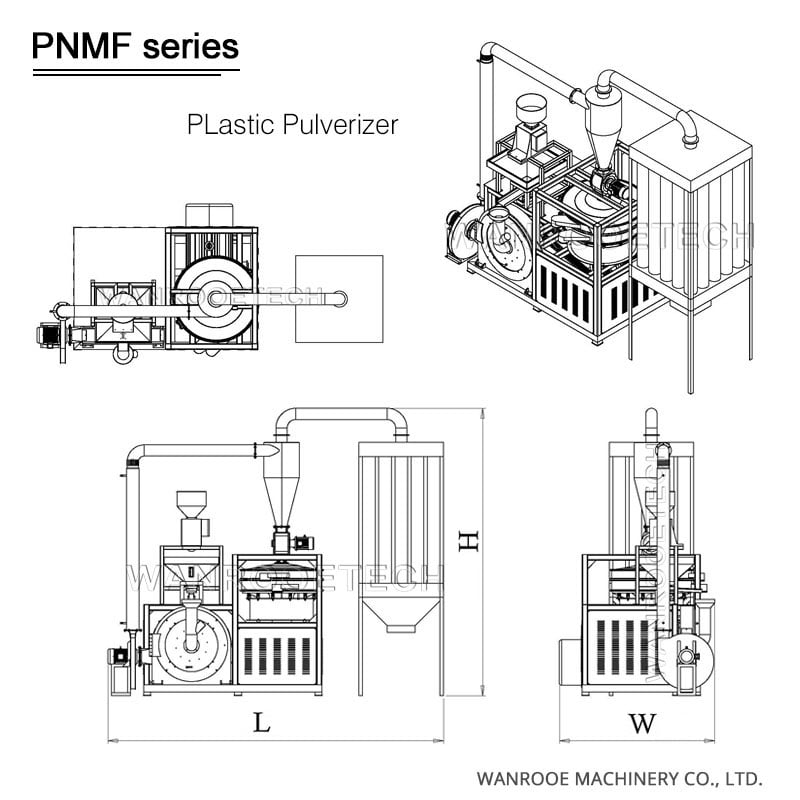

The disc grinding pulverizer machine of the PNMF series is available with disc diameter from 300 to 800 mm. These plastic pulverizer machines are high speed, precision grinders for the processing of medium-hard, impact resistant and friable materials. The material to be pulverized is introduced through the center of a vertically fixed grinding disc which is mounted concentrically with an identical high speed rotating disc. Centrifugal force carries the material through the grinding area and the resulting powder is collected with a blower and cyclone system. Depending on the application the machines can be equipped with one-piece grinding discs or grinding segments.

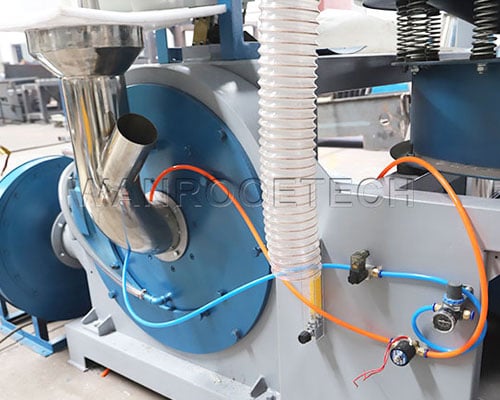

The plastic pulverizer machine is mainly composed of the electric motor, disc type blade, feeding fan, vibrating sieve, dust removing system, etc.

According to the customer's needs, you can choose some accessories, such as a converter, vacuum loader, screw loader, magnetic net, metal separator, chiller, pulse dust collector, metering and weighing packaging machine, etc.

PNMF-600 Model Plastic Pulverizer Blade:

PNMF 600 Model Plastic Pulverizer Machine Components:

|

|

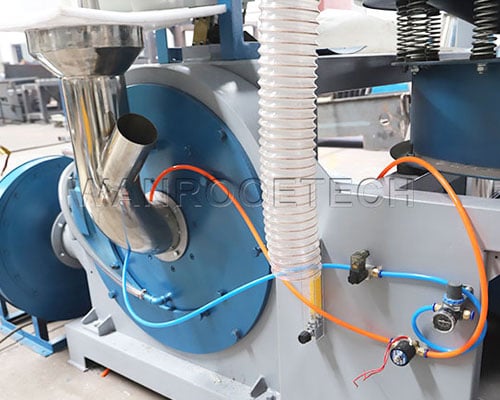

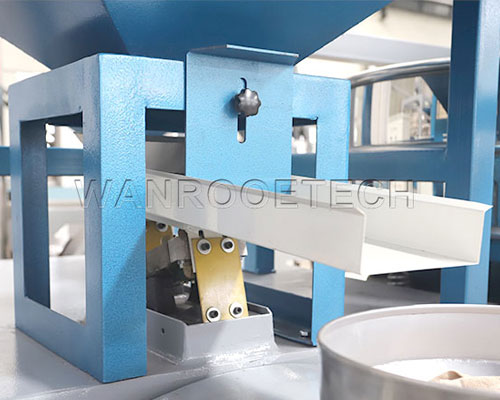

Vibratory Feeding The vibrator feeder is used to feed the material evenly into the mill, with strong magnetism, which can absorb the metal in the material and protect the mill disc. | Pulverizer Disc Pulverizer disc diameter 300-800mm, pulverizer machine fixed disc double layer, with cavity, through the water cooling. Pulverizer moving disc, atomized cooling. |

|  |

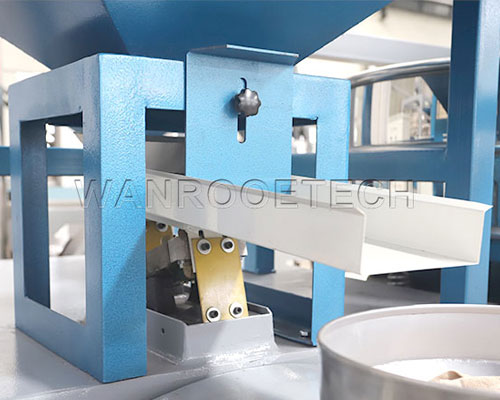

Whole Body Pulverizer Blade Hard force, working force is very large, can be customized according to the customer's material characteristics of different types of blades, standard configurations. | Segment Pulverizer Blade Segment pulverizer blade, after a long time use, only need to resharpen it, no need to replace the whole blade. A set of blades can be repaired 4-5 times, which reduces the operation cost of customers, and PNMF-600/800 can be equipped with split blades. |

|  |

Temperature Control The enhanced cooling device for automatically controlling the temperature includes a nozzle for spraying in cooling water, regulating control devices, solenoid valves, thermostats, an automatic control device and a material feeding switch. | Vibrating Screen Installation of screen according to the grinding mesh, continuous production, automatic classification and screening, easy to replace. |

|  |

Bags Type Dust Catcher Smaller footprint, lower price, can reduce the workshop dust, customers with higher requirements for environmental protection can choose pulse dust catcher. | Intelligent Control Can be adjusted according to the actual situation simple operation, save time and effort |

Technical Features:

1. The new disc design is with high quality, strong resistance and the life of this grinding disc is double the ordinary ones.

2. The newly designed professional bearings are with a high rotation rate. At the same time using only one drive motor, to ensure the efficient grinding crash, which greatly saves the time of machine operation and engineering control.

3. Easy installation and maintenance, just open the door to clean up.

4. The whole milling process is sealed, without dust leakage.

5. Full automatic design, automatically feeding, discharging and sorting.

6. Grinding gap adjustment is simple, just use the feeler gauge and adjust bolts can be fine-tuning.

7. The mill uses the water and wind double cooling system , Prevent bearing and other parts from overheating.

8. Well-known brand accessories, such as SKF bearings and Siemens motors, can work for a long time, saving the trouble of changing accessories frequently.

9. With a wide range of optional accessories, professional solutions can be developed based on the customer's budget and processing requirements.

Application Areas:

The PNMF series automatic plastic pulverizer mill is a disk-type plastic pulverizer, which has the advantages of high capacity and low-power, This machine can be used for powder processing of PE, HDPE, PP, PS, ABS, EVA, PET, nylon and other materials.

PNMF series plastic pulverizers can process powder sizes up to 20-120 mesh.