What is plastic sheet crusher?

Plastic sheet crusher is the size reduction machine that used in plastic sheet recycling business to crush the plastic sheets for recycling purpose. Plastic sheets are the products which are made of plastic materials like PET, PP, HDPE, PC, PA, etc. The plastic sheets normally are shiny, partially transparent or translucent. The weight of them are very light but they are very strong. The main feature of the plastic sheet is its good resistance to chemical attack. Because of that, the plastic sheets are widely used in storage, equipment protection, and interior decoration etc.

Why we need to recycle plastic sheet?

As we all know that, plastic sheet is very hard to break down. Some plastic sheet needs years to break down and some even could not break down and it will last forever. If we do not handle the waste plastic sheet in a right way, they will cause big harm to the environment. Recycling the plastic sheet not only helps to protect the environment, but also helps to save resources and reduce the waste. With the help of the plastic sheet crushing machine, the recycling process will become easier.

Plastic Sheet Crusher Granulator Recycling Machine Components:

|  |

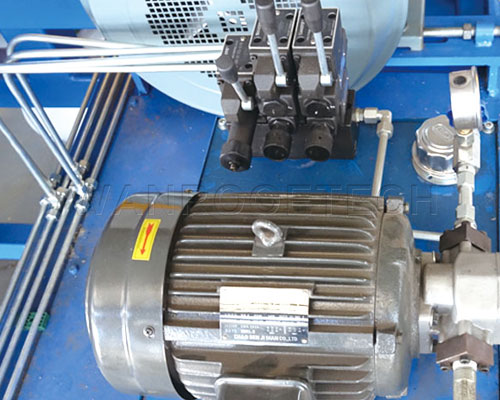

Hydraulic Connector Oil link device is installed for each machine to keep the orderliness and smooth of oil pipes. | Rotor Special“L" design rotor help the machine achieve the excellent grinding result saving the energy and reducing the noise. |

|  |

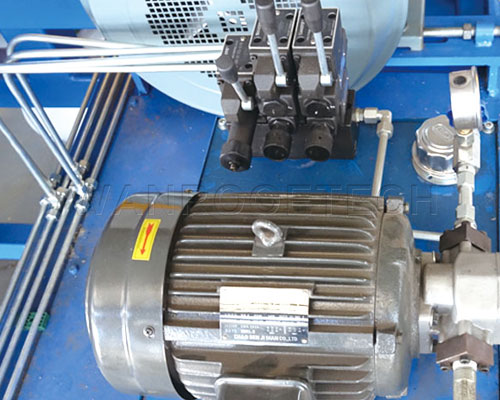

Screen Special material assures the long-life abrasion resistance of the screen.Well-proportioned high rate holes much improve the machine output. | Motor Overload Protector Equipped with electrical current relay, motor overload protector and other multiple safety devices. |

|  |

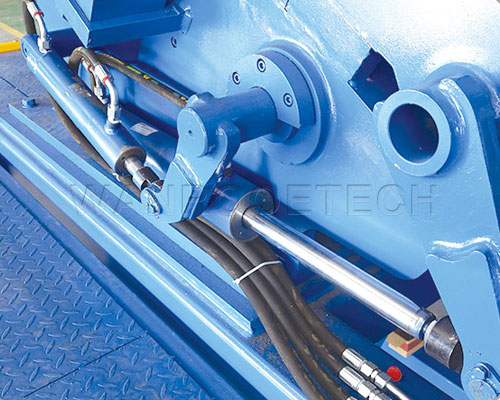

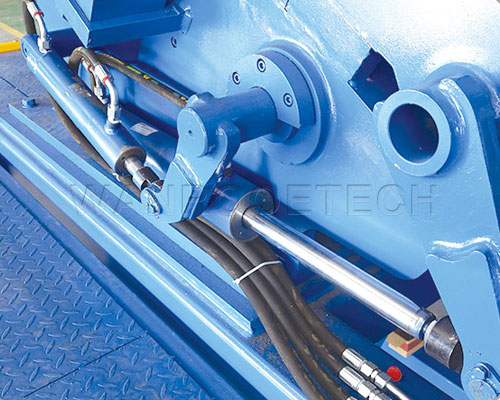

Hydraulic Cylinder Hydraulic device makes opening the chamber and screen much easier. | Metal Detector(Optional) Metal detector can be combined with belt conveyor, and can interlock with control system, to warn and stop the system, in case that metal is found in feeding. |

|  |

Hydraulic Equipment The hydraulic equipment can control the hydraulic cover opening of the crusher room, which makes the inspection and maintenance of the crusher room and the replacement of tools more convenient and fast. | Cutting Chamber lts' easy to open the full chamber, Loosen the nut, the chamber can be open within short time. |

|  |

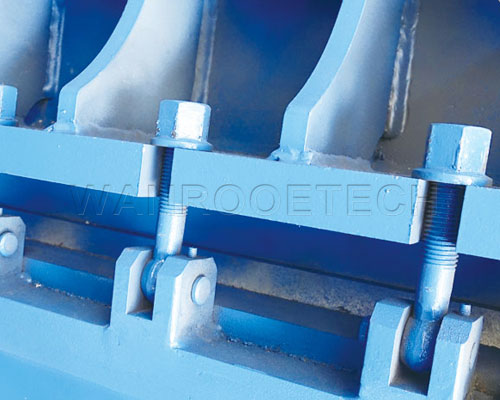

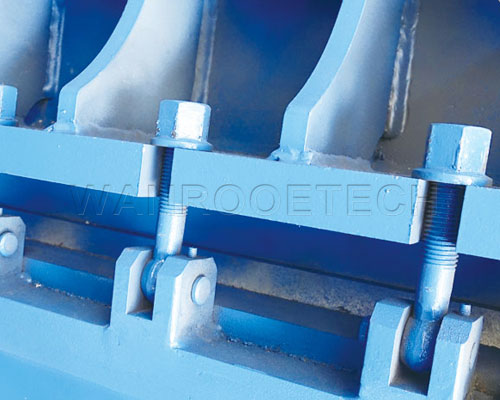

Screen Locked Device Simply design help convenient operation and reduce much time to replace the screen. | Shock Absorber Foot Foot with shock absorber to reduce vibration and eliminate noise. |

Plastic Sheet Crusher Granulator Recycling Machine Advantages:

1. The main rotor must pass the dynamic balance testing,

2. Straight rotary and fixed knives, two sets of rotary knive holders (totally 10pcs) are staggered on the rotor.

3. Main bearings are installed on outside frame for easy maintenance, and it can't be effected by material powder.

4. Opening the top cover and changing the sieve electrically, Labor saving, fast and safe.

5. With current over-load protection for motor,

6. With safety limit switch, if the top cover is not closed 100%, it can‘t be started.

7. Strong structure: A3 steel board with more thickness for the body and legs, less vibration.

8. Water spray device can be chosen to install on the top inside, it can wash the materials, cool the rotor and reduce the dust.

9. Screw conveyor or belt conveyor can be install at the bottom, for stable discharging.

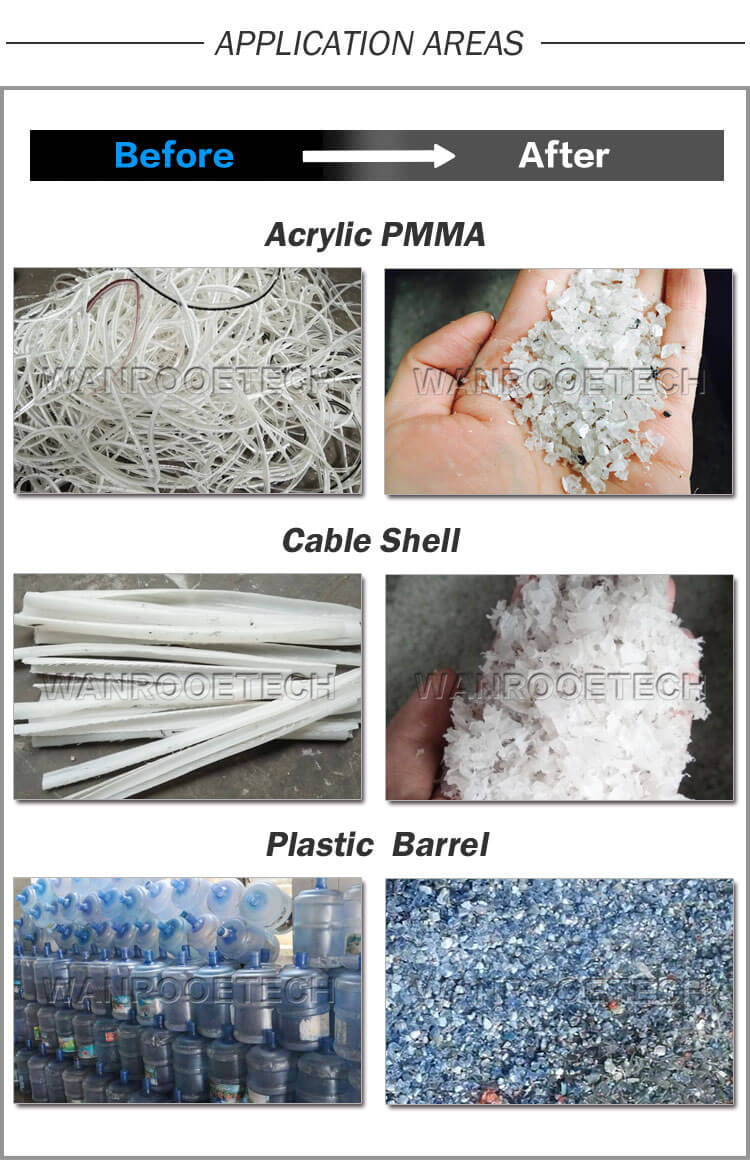

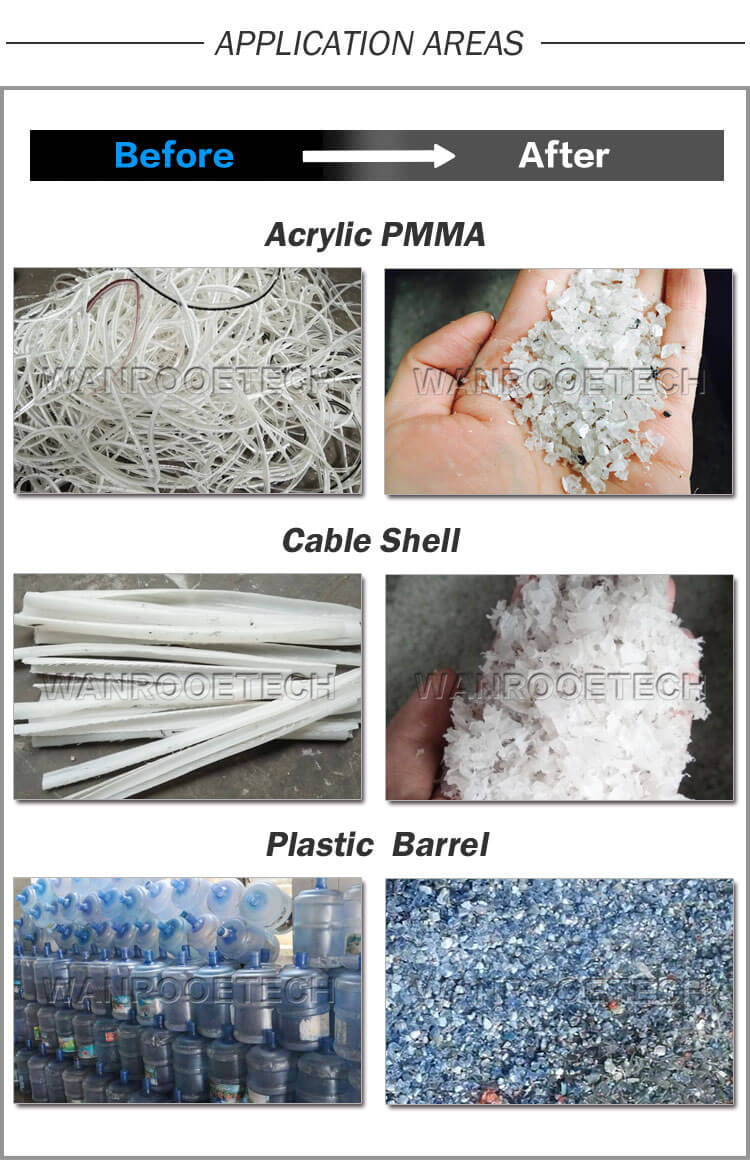

Plastic Sheet Crusher Granulator Recycling Machine Application Areas:

PNGM series heavy duty type plastic sheet crusher is suitable for the material which has big shape, high-strength, and massive capacity. For example plastic film, pipe, sheet, profile, PET bottles, hollow barrel and so on.