The capacity of lead acid battery shell recycling system ranges from 500 kg/hr to 2000 kg/hr.

Lead-acid battery shell recycling washing does not need hot washing, PP lead acid battery shell is very heavy, sinking in the bottom of the water, lead acid battery shell has calcium carbonate, so pp battery shell cleaning line, have to use SS304 stainless steel washing because the material has sulfuric acid, corrosive very large.

Why do we need to recycle PP lead-acid batteries?

Due to resource constraints and the need to control the environment, countries around the world have attached great importance to the recycling of used batteries and batteries, the management of used batteries and batteries can not be delayed, how to make used batteries and batteries resourceful and harmless has been imminent, Wanrooe machinery according to this situation developed a new waste battery recycling equipment for battery recycling has played a significant The significance of waste battery recycling equipment can be dismantled electric car batteries, car batteries, motorcycle batteries, and some unconventional battery batteries. Our waste battery dismantling machine meets the requirements of contemporary economic development and is an environmentally friendly machine. Due to the emergence of waste battery dismantling machines, a large number of waste batteries in our cities have been basically solved. The reuse of old batteries is realized, and the lead obtained after reprocessing has high economic benefits.

With the country’s vigorous promotion of new energy and high attention to environmental protection, the application of electric batteries is becoming more and more widespread, so there are a lot of used electric batteries, which are difficult to deal with. According to the unique situation of battery, our company has developed a set of automatic battery crushing and washing pelletizing lines, which can sort out the lead, acid water and plastic shells in the battery, and the plastic shells can be crushed and cleaned for deep processing and granulation.

PP lead acid battery shell recycling before and after:

|  |  |

| PP Battery shell recycling before | after PP battery box washing | Sorting out impurities |

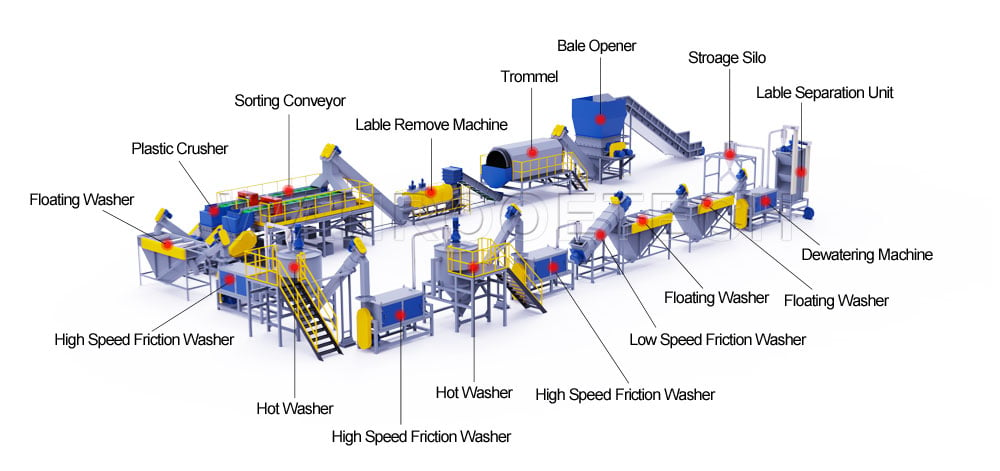

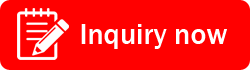

PP lead acid battery shell recycling crushing and washing process:

Waste PP lead acid battery shell recycling crushing, washing, sorting, production process instructions.

(1) The PP battery box is sent into the slow storage bin by forklift, and after the storage bin, the material can be sent into the conveyor belt for quantitative feeding at a uniform speed.

(2) Irregular materials are removed from iron through the belt conveyor.

(3) After large crusher to crush the PP battery box into an ideal state.

(4) Into the loading washing machine for high-speed friction, in the process of material and material friction with each other in the external non-stop water rinsing (this link can remove the residual dilute acid on the surface of the material)

(5) and then by high-speed vertical friction dewatering machine will be completely removed from the surface residual liquid so that the material can be smoothly carried out in the next step of the brine sinking process.

(6) The sinking and the floating separation water tank is separated by the specific gravity of brine, and all the required plastics are floated.

(7) The brine is separated from the material by loading dewatering, and the separated brine is directly fed into the flotation separation tank through the pipeline for internal recycling, and all the brine is not discharged in this process, so there is no need to go through the rolling screen and filter tank.

(8) After desalination, the material enters the clear water rinsing and sinking water ABS through the bottom spiral to the dewatering machine for dewatering treatment.

(9) The floating water PP is fished out by the automatic spiral reclaimer. It is noted here that if the treatment is floating water PP then the floating water PP will automatically enter the dewatering machine through the spiral reclaimer. Thus, automatic conversion is achieved.

(10) Dewatering process is carried out.

(11) After dewatering, the floating PP or ABS will be dried.

(12) The blower feeding system will send the material to the next process.

(13) After the drying process, the material will enter the wind separator for film separation.

(14) The drying heating sheet ensures that the material moisture is not higher than 1%, and the material is sent to the storage bin through the wind feeding system.

(15) Storage bin for material caching.

(16) In this process, there will be no brine discharge, only the adjusted brine will be replenished into the brine-specific gravity separator from time to time by the brine automatic adjustment equipment.

(17) The PP plastic obtained can be passed through the plastic pelletizer machine and made into new plastic pellets again.

Wanrooetech provides PP lead acid battery shell recycling machines, according to your recycling material, and provides customized recycling services to meet your different needs, we will help you save investment costs and labor costs, and we have professional engineers one-on-one to help you solve your questions, If you have chunks of PP lead acid battery shell sitting in factories and are interested in recycling them, Please contact Wanrooe for consulting.

If you want more information, quotation, please leave us a message! when sending the inquiry, please describe your parameters or technical requirements (such as processing materials, output size, capacity, etc.)