Automatic PVC Pipe Tube Belling Machine Description:

1. PVC Pipe Belling machine with a hauling device and program interface concerned is used with the extruding machine. It is also used solitarily.

2. While expanding pipes, the machine adopts translation. The action is steady and correct. It does not damage pipes.

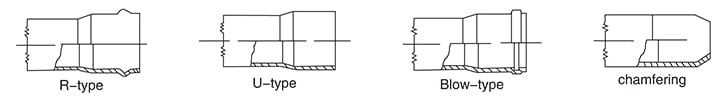

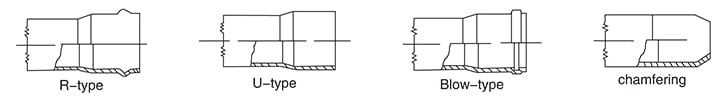

3. The machine adopts the electric heating type. Each oven is equipped with a heating core. The shaping method adopts expanding end shaping. The size of the pipe mouth is correct. On its panel, there is a transfer switch for belling solvent type socket (Straight port) and seal loop type pipe socket( R type). The choice of expanding pipe types is very convenient.

4. The technological adaptability is strong. All the key electric control elements are imported.

Automatic PVC Pipe Tube Belling Machine Applications:

PVC pipe belling machines include automatic pipe belling machines and semi-automatic pipe belling machines. It worked with mold for pipe belling, which can be linked with a plastic pipe production line and also can be used separately.

Competitive Advantage:

The capacity and other parameters are for the heating oven, the machine with a double heating oven can double capacity.

Full-auto pipe belling machine expander withdrawing device and program interface concerned is used with the extruder. It is also used solitarily. While expanding pipes, the machine adopts translation. The action is steady and correct. It does not damage pipe material. The machine adopts a double-infrared heating oven type. Each oven is equipped with a heating core. The shaping method adopts expanding-end shaping. The size of the pipe mouth is correct. On its panel, there is a transfer switch of expanding solvent type pipe socket(straight port) and expanding seal loop type pipe socket(R type). The choice of expanding pipe types is very convenient. Its main electric control elements are exported. The system characteristics are steady and reliable.