Disposable Diapers Sanitary Napkin Crusher Granulator Machine Application Areas:

Disposable diapers sanitary napkin crusher granulator machine is specially designed for crushing all kinds of Diapers, scrap diapers, sanitary napkins, sanitary napkins, diapers, pull-up pants. also can crush thick-wall resin, timber, aluminum foil in the shape of film, sheet, runner, tubular construction or hollow container. The crushing material includes PVC, PP, PE, PET, EVA, PC, Sponge, etc.

Disposable Diapers Sanitary Napkin Crusher Granulator Machine Description:

Disposable diapers sanitary napkin crusher granulator machine is specialized in crushing various kinds of plastic materials into different sizes of granules(3-8mm). Crushed plastics can be recycled for the reproduction of plastic products. This machine can help reduce the volume of plastic waste, greatly save costs and resources.

Wanrooe disposable diapers sanitary napkin crusher granulator machine is designed as tangential feeding so that feeding and swallowing more outstanding. At the same time, the feed port has a plastic cover curtain. Avoid the problem of material jumping easily by the ordinary crusher machine.

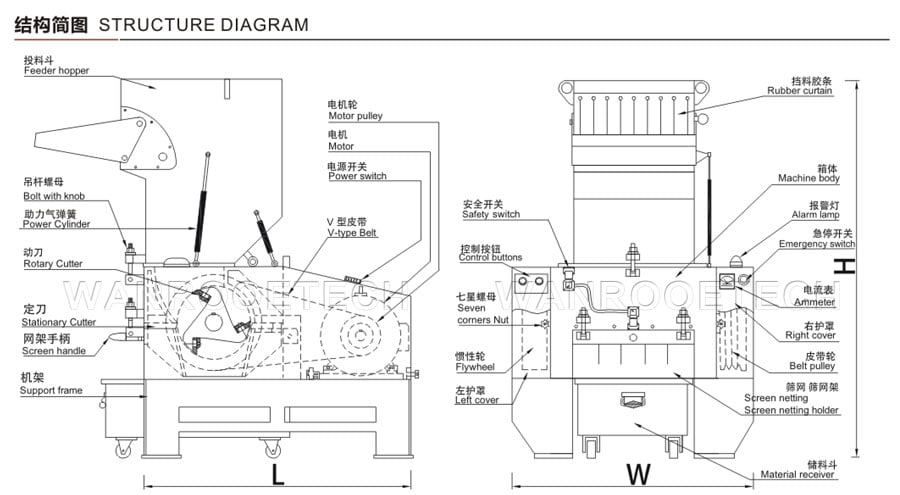

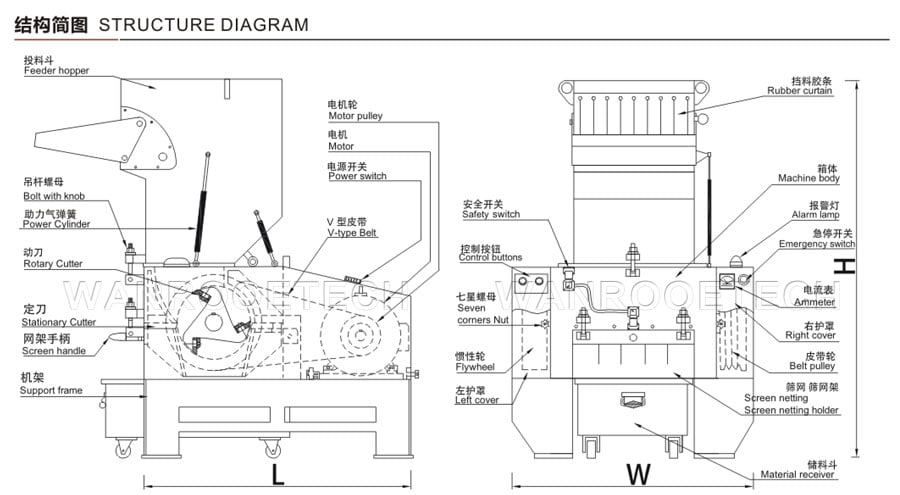

Structure Diagram:

Component:

|

|

Feeder Hopper Design Feeding hopper with double-layered on 4 sides and the inner layer is made of stainless steel with insulation material in between to provide good noise handling. | Durable Cutter Blades are made of high-strength alloy tool steel, with high hardness, good abrasion resistance, and long durability.

Adopted hexagon socket screw installation way of the blades and strong wear resistance.

Material: CR12MOV, hardness in 57-59° |

|

|

Motor Equipped with electrical current relay, motor overload protector and other multiple safety devices. | Spindle Cooling Device Unique cooling water circulation system,the heat generated by the machine to theoutside, can effectively avoid the crushingmaterial caking. |

|  |

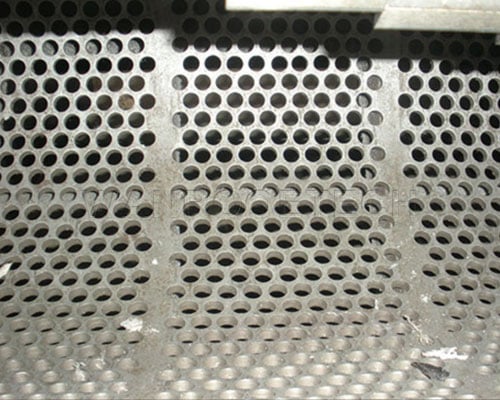

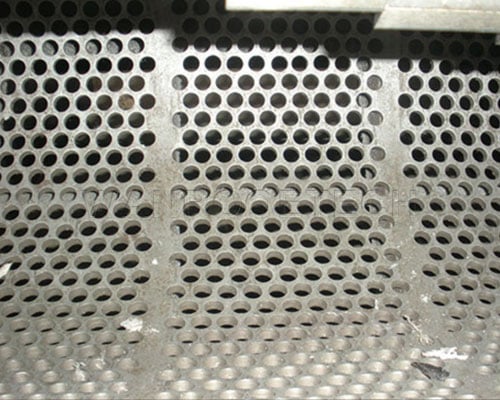

Emergency Stop Switch The red switch on the operation panel ofthe machine is mainly used as an emer-gency stop when the equipment fails. | Customized Screen Mesh Customized mesh sizes are available ac-cording to client's demand. |

|

|

Storage Bin The extended drawer can accommodate more materials and comes with universal wheels for easier movement. | Electric Component The electrical components adopt international famous brands, with high configuration and stable operation. |

|

|

Storage Silo(optional) Feeding and receiving, good sealing performance, admixture hopper set dust inlet, effective control of dust. | Belt Conveyor(optional) The plastic waste is conveyed into the crusher through the belt feeding device; The device adopts ABB/Schneider frequency converter for frequency control. The conveying speed of the belt feeding device is linked with the fullness of the crusher, and the speed of the conveyor belt is automatically adjusted according to the current of the crusher. |

Disposable Diapers Sanitary Napkin Crusher Granulator Machine Technical Features:

High quality tool materials: This series of crushers uses imported high-quality tool steel to manufacture specialized tools. These cutting tools are not only adjustable in installation, but also can be repeatedly sharpened, greatly extending their service life.

Innovative cutting frame design: The mobile cutting frame adopts a stepped design, which effectively decomposes the cutting force, doubling the cutting force and improving the crushing efficiency.

Durable tool material: The tool is made of imported SKD11 material and undergoes special processing to ensure its ultra-high durability.

High strength shaft body: The shaft of the crusher is made of advanced steel, ensuring the strength and stability of the shaft and ensuring long-term stable operation of the machine.

Enhanced crushing force design: The claw blade structure design makes the crushing force stronger and can easily meet the crushing needs of various hard materials.

Optimized feeding hopper design: The feeding hopper of the crusher has been optimized and treated with special rust prevention, effectively avoiding material leakage and pollution during the crushing process, ensuring the purity of the product.

Compliant with international standards: The product design is scientifically reasonable and strictly follows the European CE standards, ensuring the safety and reliability of the product.

Efficient cooling system: The unique cooling water circulation system can timely bring the heat generated by the machine to the outside, effectively avoiding material agglomeration during the crushing process, ensuring the crushing effect and production efficiency.