4 problems to pay attention to when using a single shaft shredder blade

Views: 901

Author: Site Editor

Publish Time: 2023-02-22

Origin: Site

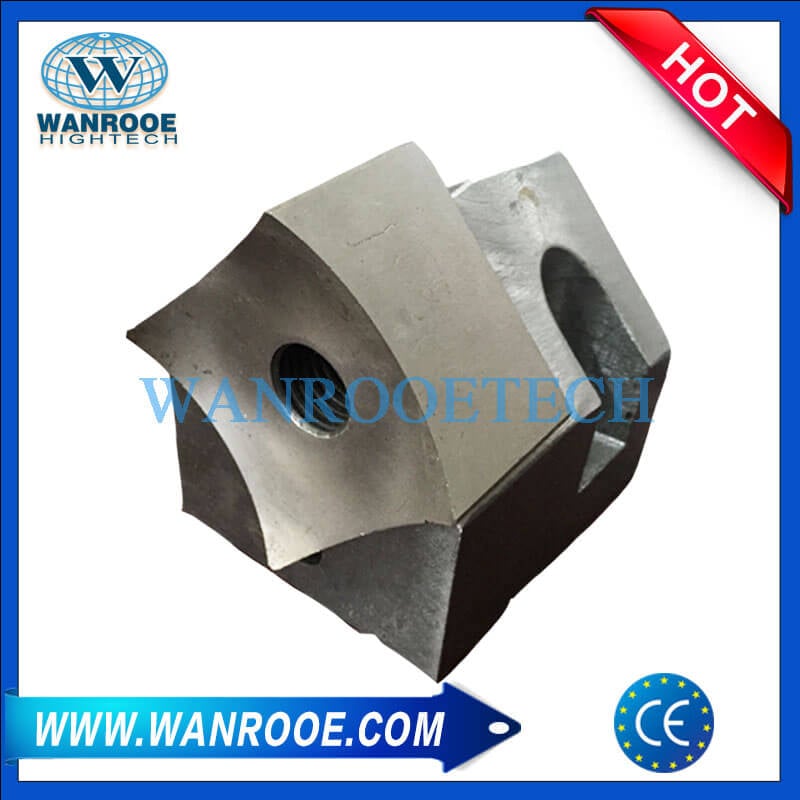

The shredder blade is one of the important accessories on the shredder. The quality of the shredder blade directly affects the processing cycle of the machine to waste. The shredder blade is widely used in metal, circuit board, plastic, waste rubber, wood and The quality of the shredder blade for the crushing of large-volume waste directly affects the processing cycle of the machine for waste. According to the classification of the shredder, the shredder blade is divided into a single-shaft shredder blade and a multi-shaft shredder blade. . As an important shredding knife on the shredder. According to the classification of shredder structure, shredder blades can be divided into single-shaft shredder blades (square knife), multi-shaft shredder blades (including double-shaft shredder blades and four-shaft shredder blades). Our company adopts high-quality steel, and after forging, finishing, quenching, packaging, and other processes, we provide you with high-quality, cost-effective blades. Welcome to buy!

The commonly used materials for single-shaft shredder blades are SKD-11/DC53/D2/Cr12MoV/9CrSi. According to the quality, the single-shaft blade made of Cr12MoV is the most cost-effective. After vacuum quenching, its hardness and wear resistance are higher than ordinary materials, and the hardness reaches 60-62HRC, which better exerts the physical characteristics of the material and greatly improves the service life. The moving knife has 4 cutting openings, which can be rotated 90 degrees after wear and continue to be used. Mainly used for shredding wood, rubber, plastic, paper and other waste materials. Compared with the multi-shaft shredder, the design of the single-shaft shredder is more complicated, but the replacement of the knife mold is more convenient. The blade of the single-shaft shredder can be easily replaced by simply removing the fixing screws, while the multi-shaft shredder It is necessary to dismantle the entire case and take down the shaft before it can be used. Therefore, in terms of the convenience of changing the knife mold, it is easier to maintain than the double-shaft shredder.

What problems should be paid attention to when using single-shaft shredder blades

1. Make sure the machine is normal

If you want the single-shaft shredder blade to work normally, exert a powerful cutting effect, and create precise working standards and effects, you must first ensure the normality of the shredder. Therefore, a very important item before our work is to conduct a comprehensive inspection of the shredder, especially the safety performance of some important operating parts, especially whether the lubrication effect of claws, hammers, blades, etc. is normal, because these are directly related to The normality of the paper shredder.

2. Grasp the blade and temperature of the shredder during use

In the process of using the shredder, our construction personnel must have high professional skills. Sometimes they have to be very careful about the operation of the shredder blades. If you find that there is a blockage or a problem with the cutting edge, you should stop and clean it in time. Replace the cutting edge to ensure the normal progress of the work. When we are overloaded, the machine temperature is too high and the waste will be ejected. At this time, we should remove obstacles in time.

3. Pay attention to details after troubleshooting

When we encounter a problem with the shredder and deal with it accordingly, we don't add material immediately, but let the blade of the single-shaft shredder idle for a few seconds. If the equipment is damaged by filling immediately when the mechanical speed is too low, then there is no way to bring it back at will, which will cause the temperature to rise and explode if the speed is too fast.

4. It is very important to strengthen and check the blade during work

When our cutting work is going on for a long time, we must pay attention to regular parking to strengthen the blade and power machine. Unnecessary accidents happen. If it is a long-term assembly line operation, the blade of the single-shaft shredder must be placed on the machine base. It is more stable, more convenient and safe to work. Therefore, only when the cutting edge is blunted or cracks, curling, openings, etc. are found, the blade must be replaced in time to ensure the smooth completion of the work and the high standard of cutting.