Lithium Ion Battery Disposal Recycling Plant

Lithium ion battery disposal recycling plant is a mechanical and physical way to recycle lithium batteries with lower energy consumption, which is an environmentally friendly and efficient method. Based on the structural characteristics of lithium battery negative electrodes, a combination of discharge shredding crushing and screening and airflow sorting process is used to separate them in order to achieve efficient separation and recovery of copper, aluminum and carbon powder from waste lithium battery negative electrodes so that lithium batteries can be recycled. With the development of industry environment optimization, the development prospect of lithium battery resource utilization is promising.

Why do we need to recycle lithium-ion battery?

Lithium-ion batteries basically consist of a negative electrode (anode), a positive electrode (cathode) and a diaphragm. The electrode is made up of a conductor foil coated with a mixture of binders, active materials and additives (battery slurry). Improper disposal of used lithium-ion batteries not only causes environmental pollution but also causes the problem of wasted resources. By recycling lithium-ion batteries, we not only avoid pollution of the environment but also optimize the allocation of resources, prompting secondary use of resources and saving energy.

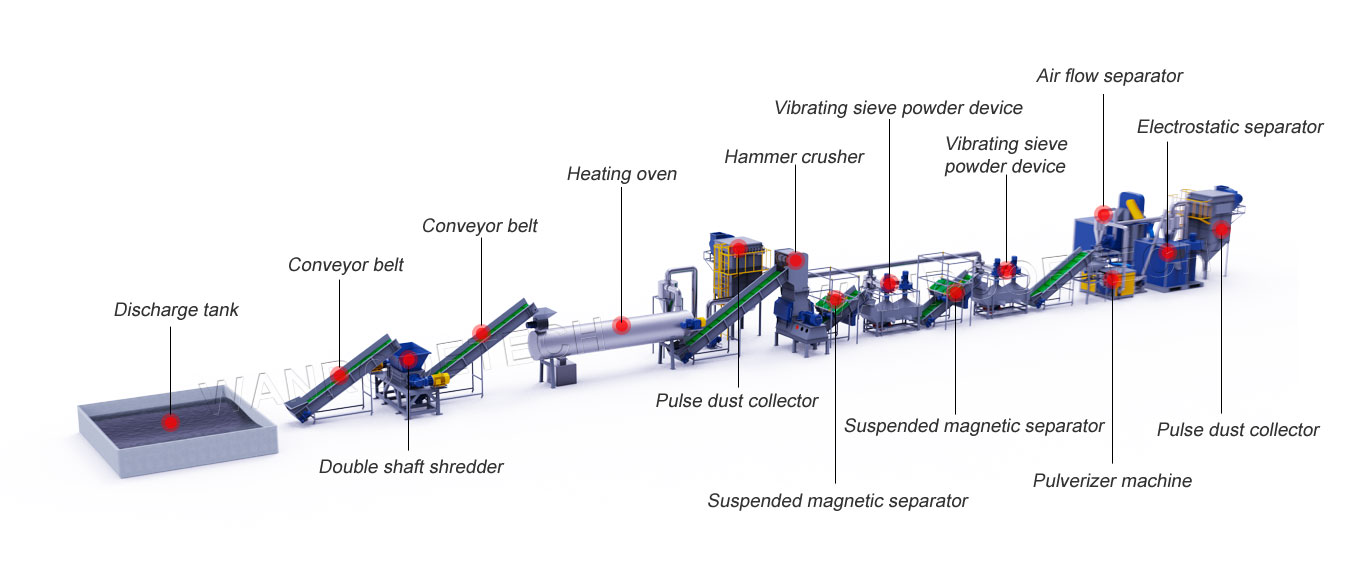

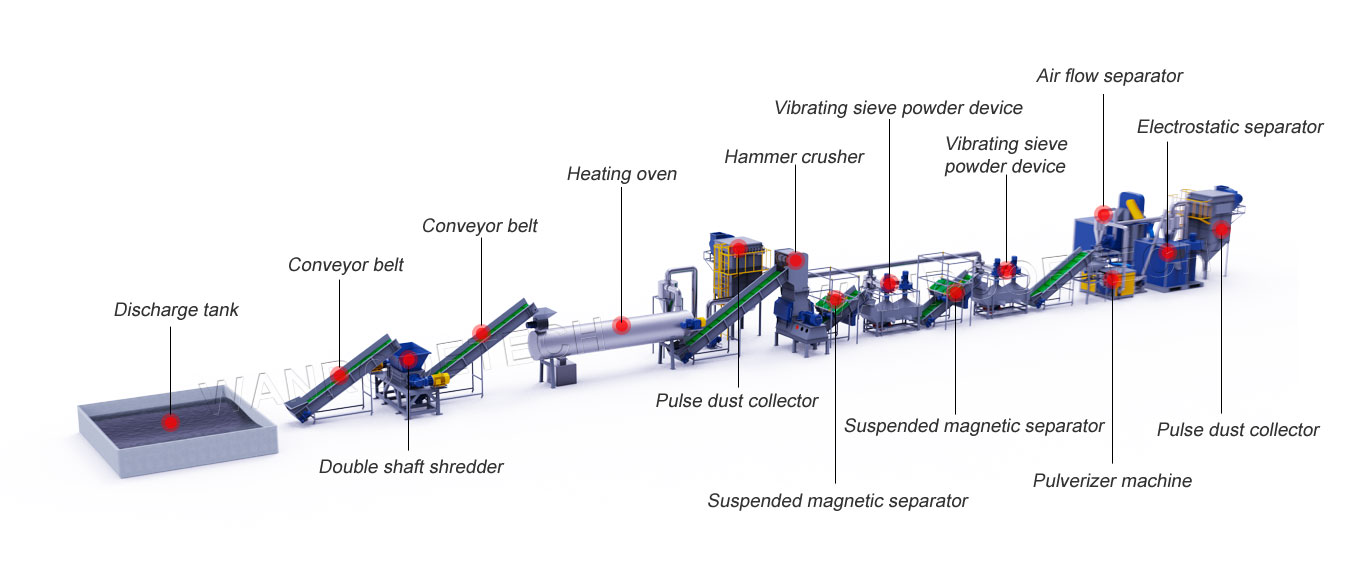

Lithium Ion Battery Disposal Recycling Process:

Discharge tank → Conveyor belt → Double shaft shredder → Heating oven → Hammer crusher → Suspended magnetic separator → Suspended magnetic separator→ Vibrating sieve powder device → pulverizer machine → Air flow separator → electrostatic separator → Pulse dust collector

1. Discharge tank: discharging the used lithium batteries to a non-electric state by self-discharging or immersing them in salt water to obtain non-electric lithium batteries.

2. Conveyor belt: transporting the uncharged lithium batteries to the shredder.

3. Double shaft shredder: the lithium battery is shredded and processed and may catch fire during the shredding process, so it can be filled with nitrogen during the shredding process, or a more economical way is to put water in a bucket and add water.

4. Heating oven: using electric heating, used to dry the battery electrolyte and moisture.

5. Hammer crusher: to crush lithium batteries into 8-20mm.

6. Suspended magnetic separator: remove the iron from the lithium battery.

7. Suspended magnetic separator: separating the metal for the second time and separating it a bit more clearly.

8. Vibrating sieving powder device: separating the carbon powder at the bottom and separating the insulation diaphragm at the top.

9. Pulverizer machine: grinding the metal into 15-20 mesh powder.

10. Airflow separator: the powder after grinding and then specific gravity sorter, separating carbon powder, copper powder, aluminum film powder, etc.

11. Electrostatic separator: optional, further separation of metal powder.

12. Pulse dust collector: to purify the dust of the complete lithium battery recycling equipment.

Raw materials:

Lithium battery disposal recycling solutions are used to dismantle and recycle mobile phone batteries, car batteries, rechargeable batteries, electric car lithium batteries, soft pack batteries, shell batteries, cylindrical batteries, etc. Different types of lithium batteries have different recycling procedures.

|

|

| Soft package lithium battery | Cylindrical battery |

|

|

| Hard shell lithium battery | Positive negative plates |

Final product:

The final products are graphite powder, lithium cobaltate, aluminum and copper.

|

|

| Copper | Aluminum |

|

|

| Cobalt Acid Lithium | Graphite Powder |

Lithium Ion Battery Disposal Recycling Plant Working Principle:

The lithium battery disposal recycling equipment production line first discharges the lithium battery with electricity through the discharge tank, and then sends it to the double shaft shredder through the conveyor belt material for shredding, and the shredded lithium battery goes into the heating oven to dry the electrolyte and moisture of the battery, and then sends it to the hammer crusher through the conveyor for crushing, and the crushed lithium battery goes into the suspended magnetic separation, which can sort out the iron in the lithium battery, and then through the second level of suspended magnetic separation The second separation of metal, the metal in which will be separated more cleanly, after the separation of lithium batteries through the vibrating sieve powder device at the bottom to separate the carbon powder, the upper part of the separation of the insulation diaphragm. The powder state of the lithium battery processed through the pulverizer machine is fed by the negative pressure system into the cyclone separator for air filtration and falls through the fan to the airflow separator so that the different densities of the material are layered to get the metal sorted out and further separated from the metal powder through the electrostatic separator while all the non-metals are brought into the pulse dust collector by the negative pressure system for concentration. The filtered tail gas will continue to be sent by the negative pressure system to the tail gas treatment equipment for air purification to meet emission standards before being discharged into the air.

Lithium Ion Battery Disposal Recycling Plant Features:

1. Humanized design, PLC automatic control, easy maintenance.

2. Lithium battery disposal recycling equipment operates in a negative pressure state, with no dust leakage, and separation efficiency of up to 99% or more.

3. eliminating the process of manually dismantling the battery to obtain the positive electrode piece, directly crushing the lithium battery, crushing the battery as a whole and separating the materials in the battery through the subsequent physical and chemical treatment process, saving time and effort.

4. the whole lithium battery disposal recycling equipment is environmentally friendly, avoiding pollution of the environment.

5. the recovered product can be used for secondary use and has a very high economic value.

6. Can be customized according to the actual needs of customers.

In order to better provide you with a professional answer, when sending an inquiry, please describe your parameters or technical requirements (such as processing materials, output size, capacity, etc.), we will reply to you as soon as possible!