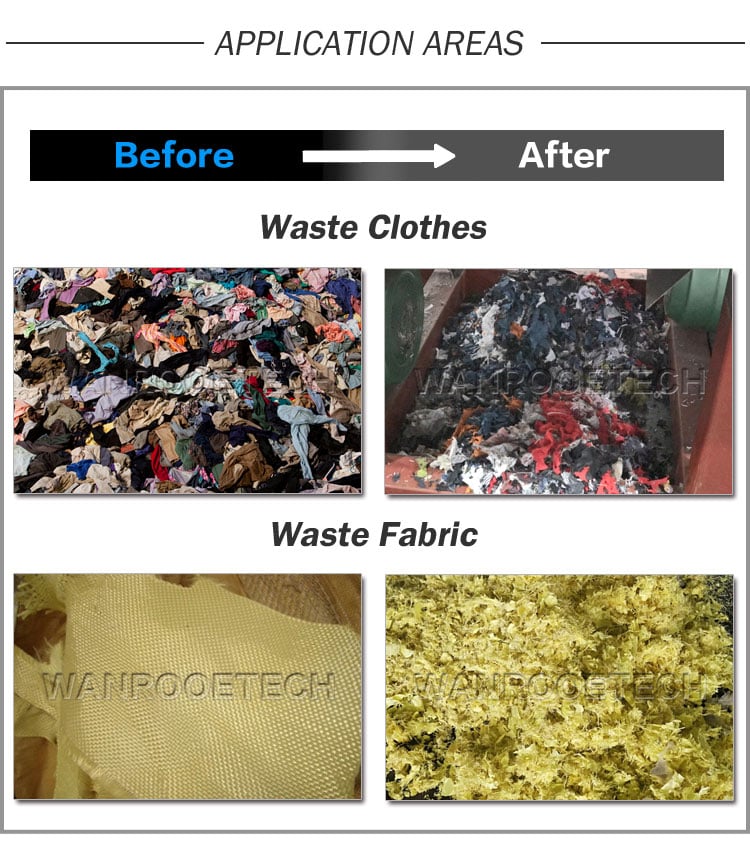

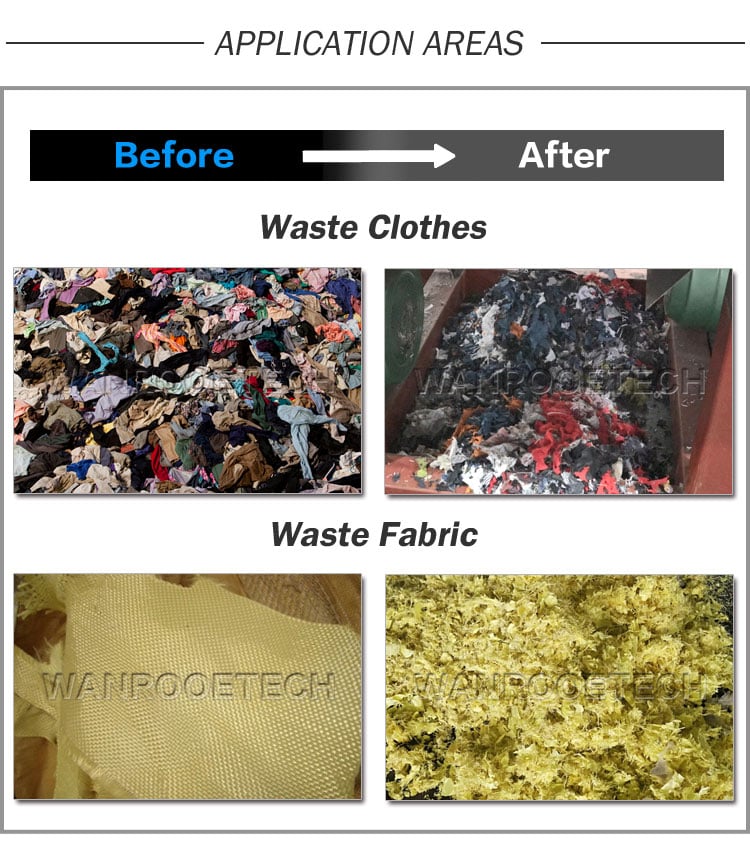

Waste Fabric Clothing Textile Shredder Application Areas:

Scrap textile shredder machine is double single shaft shredder, it is suitable for crushing all kinds of waste clothes, waste cloth, machine head material, all kinds of waste corner material, all kinds of waste edge foot material, old clothes, cowhide, fiber, old shoes, carpets, quilts, clothes and all kinds of waste life, office supplies, etc. The discharging size can be adjusted according to the user's requirement.

All of these varieties of fabric waste can be shredded consistently and easily with our range of Wanrooe shredding equipment and textile shredder. The resulting materials can further add value by making RDF(refuse-derived fuel) fuel pallets.

Waste Fabric Clothing Textile Shredder Description:

Textile shredder machine is a widely used in medium, low speed high torque of crushing equipment. With the unique design of rotor and cut chamber, the rotor knives and the counter knives cut materials perfectly so that it can not only cut materials evenly but also reduce the dust of the raw materials reasonable. It can reduce the wear of knives and screen. Rotor shaft surface can be build-up welding wear-resisting layer, making the shredder more suitable for the easily wearing material to have the most abrasion performance and better usage rate.

Why do we need textile shredder?

Textile shredder is a very helpful size reduction machine in garment recycling. Speaking of garment recycling, people always thinking of garment balers. It can bale used clothes/garment donated or re-sold to the place where people who do not able to afford new clothes. So it gives new value to the used garments. Some people do not quite understand the value of textile shredder. It seems that using the garment shredder to shred the used garment is a total waste. Because the shredder will destroy the garment and shred them to pieces. So shredded textile could not be able to use anymore. In fact, that is a misunderstanding. Garment shredder is as important as balers in textile recycling industry.

As we all know, there is a very critical step in garment recycling is sorting. Textile can be further separated into several groups for different recycling purposes. Some of the garments can be reused. So they are baled and sent to places where people need them. Some of the garment which is in good condition can even be sent to the second-hand shop for re-selling. The rest scraps are shredded by textile shredder into much smaller pieces for next processing. For example, the scraps sent to the flocking industry are used to produce filling material for furniture padding, panel linings, loudspeaker cones, and car insulation.

Working principle:

Double single shaft textile shredder Machine uses dual-motor to drive dual-gearbox, turn high rotate speed of the electric motors into the low rotate speed of cutter rollers by gearboxes, then cutting, squeezing, and tearing big materials, shred them into small broken pieces.

The rotate speed of the cutter roller is nearly 10-25RPM. The low rotate speed with high torque force. And the materials of cutters are high-quality alloy steel with good abrasion resistance.

Double Single shaft shredder Blade:

Waste Fabric Clothing Textile Shredder Fabric Shredding Machine Features:

|  |

V-cutting rotor design with staggered cutter positioning | Heat treated rotor knives Special DC53 steel (hardened) four edges use before replacement |

|  |

Twin Rotors Design Twin rotors design, generating tearing and shredding effect; | Wear Resistant Tungsten surface coating for abrasive applications |

|  |

Big-volume hopper For efficient feeding and applicable to be connected with an in-feed conveyor | Replaceable screen at the outlet For controlling shreds under the required size. The size of the screen hole is customizable |

|  |

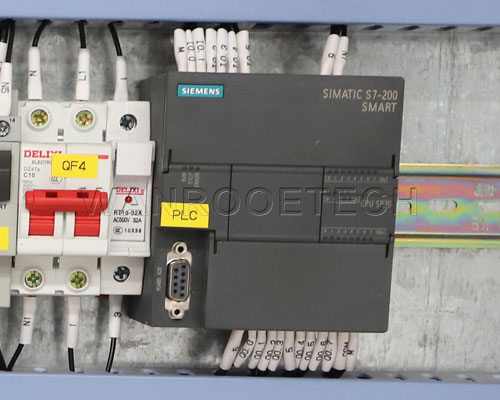

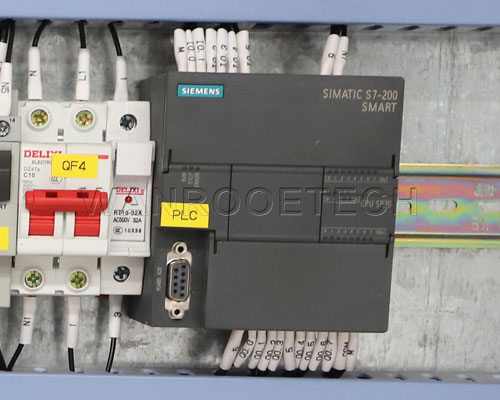

PLC control Making it easier for fault diagnosis and maintenance | Dual motor design For increasing the output |