Industrial Waste Fishing Net Shredder Application Areas:

Industrial waste fishing net shredder can process all ranges of the fishing net including cast net, bottom trawl, dragnet, drift net, drive-in net, fyke net, gill net, haaf net, hand net, landing net, seine net, surrounding net, lift net, tangle net, and lave net.

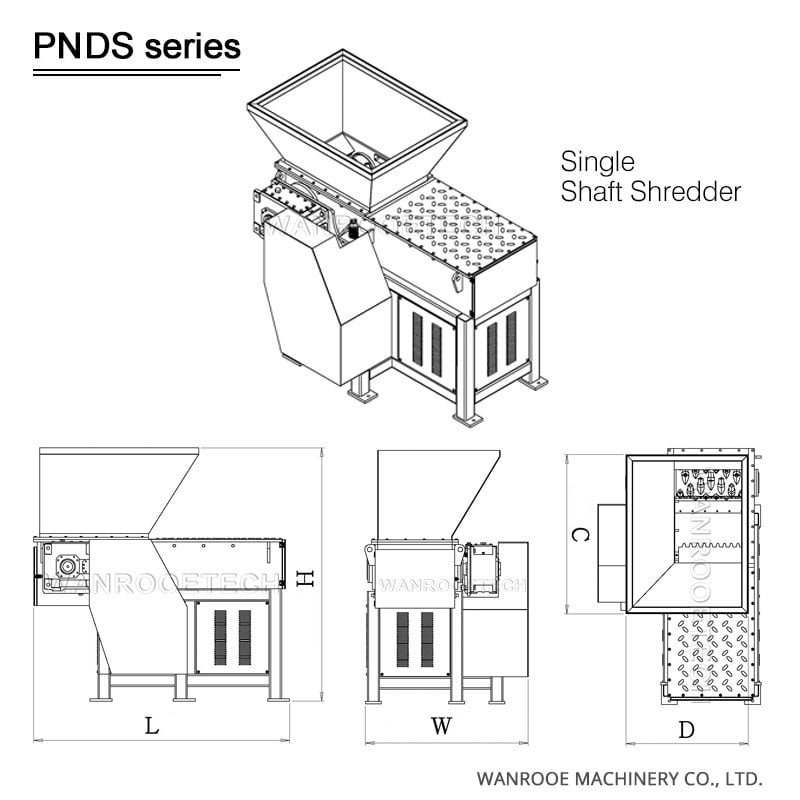

Industrial Waste Fishing Net Shredder Description:

Fishing net shredder(fishing net crusher) is recycling equipment for fishery plastic waste such as old/abandoned fishing nets(ghost fishing). Nets are devices made from nylon or PP fibers woven in a grid-like structure. They are widely used in the fishing industry to harvest fish. Nonetheless, the discarded nets are deadly to marine animals, because they can entangle and suffocate species in the ocean. Over the past years, fishing nets are seen as another plastic pollution in the ocean, after plastic bottles and plastic films.

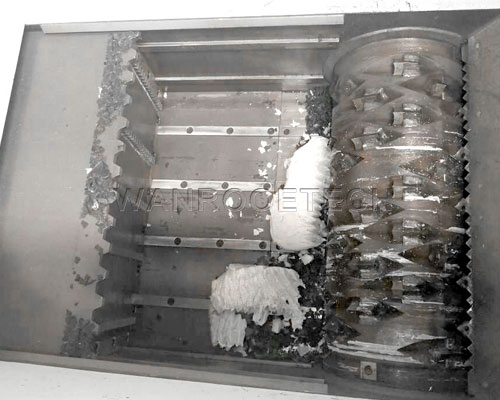

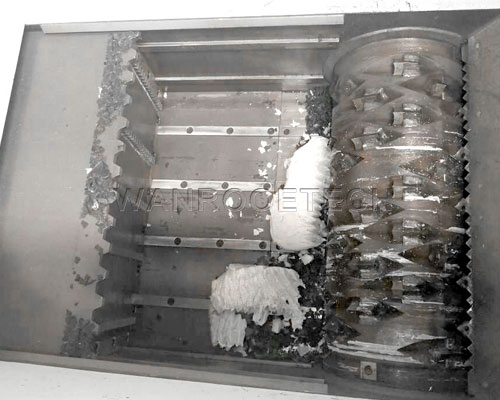

Single shaft shredder Blade:

Industrial Waste Fishing Net Shredder Components:

|  |

Pusher System Reinforced baseplate can reduce the impact caused by material entering the cutting chamber. A dust collection device is equipped at the bottom of the pusher system to guarantee the long-term stable performance of internal components. | Heat treated rotor knives Special DC53 steel (hardened) four edges use before the replacement |

|  |

V-cutting rotor design with staggered cutter positioning | Wear Resistant Tungsten surface coating for abrasive applications |

|  |

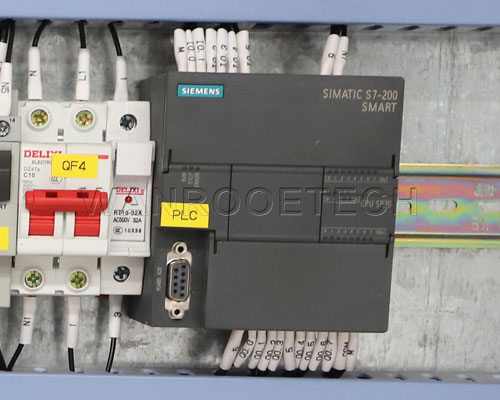

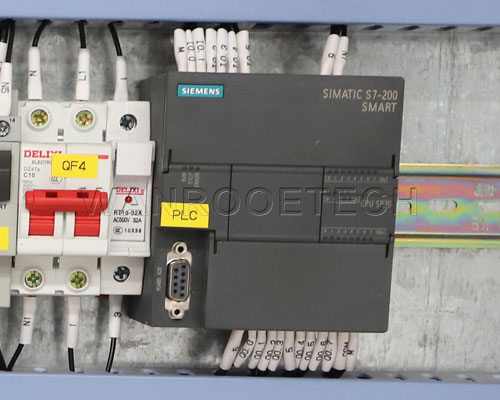

Control panel Equipped with independent and reliable electrical control panel like SIEMENS PLC control system, DELIXI contactor, SCHNEIDER Electric, etc. Manual & automatic operational modes to choose, quite flexible and safe.Motor overload protection.

| Screen Unit Wide range of screens with a variety of configurations and mesh sizes are replaceable based on customers' production requirements. The paper shredder will automatically stop while opening the screen unit to ensure operator safety. The screen is produced and mounted in sections, allow for easy maintenance. |

|  |

PLC control Making it easier for fault diagnosis and maintenance. | Hydraulic Station The pressure and rate of flow can be adjusted according to different materials. |

Industrial Waste Fishing Net Shredder Features:

Suitable for a wide range of raw materials and high production capacity: This shredder has strong adaptability and can handle various raw materials, including fishing nets, safety nets, nylon ropes, etc., and has a high hourly production capacity, which can meet large-scale processing needs.

Excellent crushing effect: Adopting a unique blade shaft structure and rotating blades, it can crush fishing nets and other materials into small pieces during the production process of low speed and high torque, effectively avoiding the phenomenon of entanglement or jamming of equipment.

Strong durability: The cutting tools are made of alloy material, which is durable and wear-resistant, and also compatible with most metal parts. At the same time, high-strength heavy-duty specialized steel is used for processing and refining, providing powerful power for cutting.

High degree of automation: The equipment adopts PLC programmable control, with high degree of automation, easy operation, and equipped with various safety protection measures to ensure stable and safe operation.

Environmental protection and energy conservation: By shredding, the volume of fishing nets can be reduced, reducing occupancy and transportation costs. Simultaneously using low-energy motors is more environmentally friendly and energy-saving.